PLA Bi-component Staple

Specification: Titer: 1.5Denier-5Denier, Length: 6~64mm

Application: Non-woven fabrics/thermal bonding/fillers. etc

Request a QuotePLA Bi-component Staples are a leading and distinctive product of eSUN Fiber, with mature production technology and stable product quality. The product is a bicomponent skin-core structure composite fiber, made of 100% polylactic acid, where the sheath component is made of low melting point polylactic acid with good softness, and the core component is made of high melting point polylactic acid with high strength.

After heat treatment, part of the sheath layer of the PLA Bi-component Staples melts and acts as an adhesive, while the rest retains the fiber state. The fibers are interconnected, forming a non-woven fabric body without the use of adhesives, and it also features a low thermal shrinkage rate.

PLA Bi-component Staples have a wide range of processing suitability. All the main non-woven fabric processing methods can be used, such as CALENDER, THROUGH-AIR, NEEDLE PUNCH, WET LAID, AIR-LAID, and SPUNLACE. These fibers are particularly suitable for producing sanitary materials, thermal insulation fillers, filter materials, etc., through the hot air penetration process. They are also the best choice for all degradable non-woven fabrics, glue-free cotton, and natural composite board bonding materials.

Titer: 1.5Denier-5Denier,

Length: 6~64mm

PLA Bi-component Staples are processed into products like thermal-bonded, hot-rolled, needle-punched, and spunlaced non-woven fabrics. These are further used in fast-moving consumer goods such as disposable hygiene materials, packaging materials, and medical supplies. Due to the characteristics of bicomponent PLA fibers, which include softness, low-temperature processability, non-toxicity, non-irritability, and lightweight, they are ideal materials for manufacturing a series of hygiene products like sanitary napkins and diapers.

Utilizing the difference in properties of the two components, the shrinkage difference is generated after stretching and heat treatment, causing the fibers to produce permanent three-dimensional natural curls. Therefore, it can be widely used as fillers, such as flakes, stuffed toy fillings, mattresses, etc., plus Its natural drying, antibacterial and deodorizing properties have wide application advantages in the fields of baby products, elderly products and pet products.

Widely used in disposable sanitary materials (including diapers, sanitary napkins, underpads, healthcare mats, etc., used for surface layers, bottom layers, and wrapping materials). PLA Bi-component Staple is an ideal thermally bondable fiber, mainly used for the thermal bonding process of non-woven fabrics. This is a form of "point bonding" rather than "area bonding," thus the product possesses characteristics such as bulkiness, softness, high strength, and oil absorption.

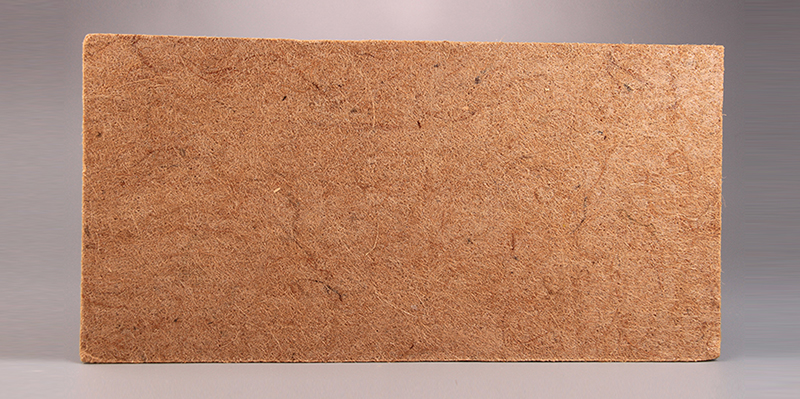

PLA Bi-component Staple include filter materials, horticultural domestic materials, insulating materials, adsorptive materials, packaging materials, rigid fiberboards, automotive wall materials, and padding materials, among others.