Thermal bonded non-woven fabrics are widely used in daily production and life. The application advantages of PLA thermal bonded non-woven fabric still lie in its biocompatibility and biodegradability. At the same time, in terms of related physical properties, PLA thermal bonded non-woven fabric also has excellent performance in practical applications.

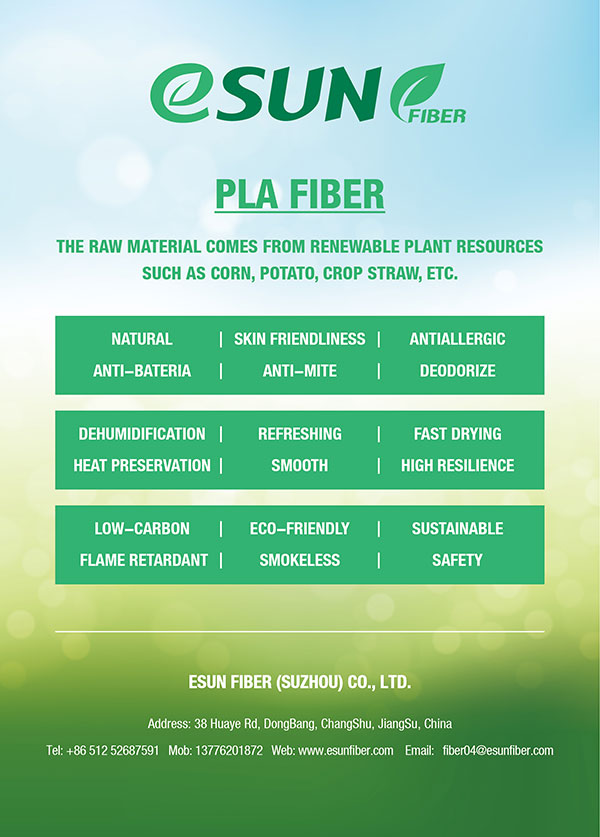

This article will mainly focus on the characteristics and applications of eSUNFiber PLA thermal bonded non-woven fabric.

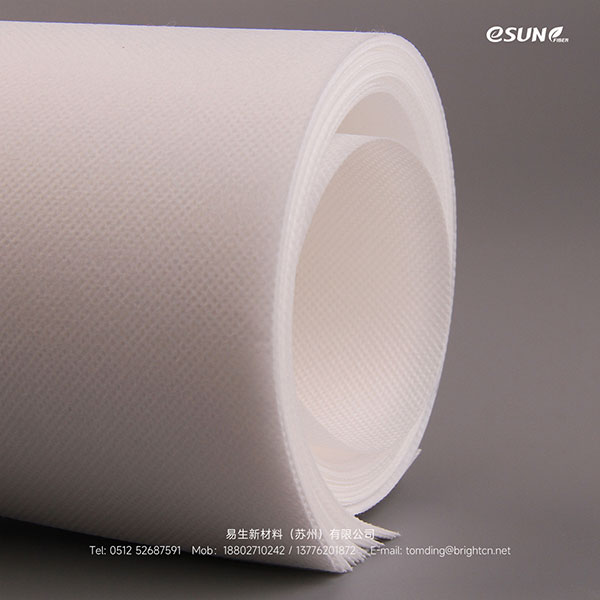

eSUNFiber PLA Thermal Bonded Non-woven Fabric

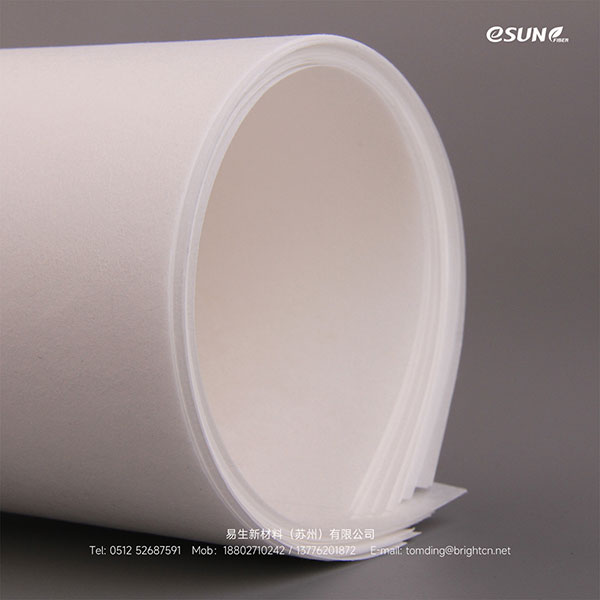

△ eSUN PLA Thermal Bonded Non-woven Fabric

△ eSUN PLA Smooth Surface Thermal Bonded Non-woven Fabric

1、Product Specifications

Gram: 20gsm-200gsm;

Width: 7cm-220cm

2、Product Features

① High strength, strong wear resistance

The hot-rolling process makes the fibers interlock and tight, thus the non-woven fabric has high strength and good wear resistance, suitable for a variety of application scenarios.

② Good breathability

Since it is made by hot rolling rather than weaving, the thermal bonded non-woven fabric usually has good breathability, which is conducive to the circulation of air and water vapor.

③ Softness

The thermal bonded non-woven fabric has a soft touch and comfortable feel, suitable for products that come into direct contact with the skin, such as diapers, sanitary napkins, wet wipes, etc.

④ Strong water absorption

The interlocking fiber structure of the thermal bonded non-woven fabric gives it strong water absorption, commonly used for making absorbent products, such as wet wipes, cleaning cloths, etc.

⑤ Antibacterial, non-toxic, non-irritating

PLA comes from lactic acid, which is an endogenous substance in the human body, and the pH value of the fiber is almost consistent with that of the human body, giving PLA fiber good biocompatibility, excellent affinity with the skin, non-allergenic, good product safety performance, natural antibacterial properties, and mold and odor prevention.

⑥ Good environmental protection

PLA thermal bonded non-woven fabric is made from renewable plant resources, which can reduce the use of petrochemical resources. In addition, PLA material has good biodegradability, which can achieve industrial compost degradation and reduce pollution.

3、Product Applications

Thermal bonded non-woven fabric has a wide range of applications in various fields, mainly including the following directions:

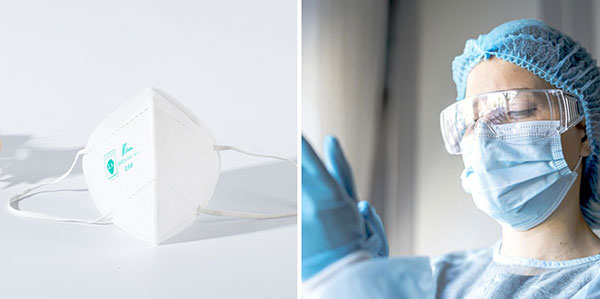

① Medical and health supplies:

PLA thermal bonded non-woven fabric has the characteristics of softness, breathability, good biocompatibility, and hygienic hydrophilicity, so it can be widely used to make disposable medical and health supplies, such as medical masks, surgical gowns, nursing pads, etc.

② Personal care products:

In personal care products, such as diapers, sanitary napkins, etc., thermal bonded non-woven fabric is often used as the bottom or surface material, its softness, water absorption, skin-friendly antibacterial properties make it an ideal material for these products. Additionally, its biodegradability well addresses the "white pollution" problem caused by disposable medical and health supplies.

③ Packaging materials:

PLA thermal bonded non-woven fabric is also commonly used in the packaging field, such as making food packaging bags, shopping bags, gift packaging, shoe box liners, etc., its biodegradability can reduce the impact on the environment.

④ Agricultural applications:

PLA thermal bonded non-woven fabric is used as agricultural cover materials, plant protection covers, etc., to protect crops, increase yield, and also benefit soil protection and ecological environment protection.

In addition, PLA thermal bonded non-woven fabric can also be used in household items, textiles, and other fields, its biodegradability and good physical performance provide sustainable and environmentally friendly options for these applications.

About eSUNFiber

eSUNFiber focuses on developing and strategically expanding polylactic acid fiber and non-woven fabrics as main products.eSUNFiber has one 10,000 tons/year melt-spun polylactic acid fiber production line, one 1,000 tons/year polylactic acid hot air non-woven fabric production line, and three functional polylactic acid fiber production lines. Among them, the three functional polylactic acid fiber production lines have an annual capacity of 5,000 tons and can produce various differentiated products such as three-dimensional curled fibers, dual-component PLA fibers, profiled fiber, polylactic acid yarn, and solution-dyed polylactic acid fibers.

eSUNFiber's polylactic acid fibers and non-woven fabrics have successfully passed the compost degradation test certification by DIN CERTCO (German Standards Association Certification Center). Regarding product safety, eSUNFiber's PLA non-woven fabric products have passed skin sensitization tests, ensuring product safety performance! Additionally, after testing by professional institutions, eSUNFiber's polylactic acid fibers have shown good antibacterial effects.

Welcome your inquiry and cooperation with us!