Small Tea Bag, Big Impact – Innovative Applications of Polylactic Acid (PLA) Fiber

The tea bag industry has experienced rapid growth due to the "measured, hygienic, convenient, and fast" benefits of tea bags.

Tea bag filter paper, as the essential packaging material, must allow effective diffusion of tea's active ingredients into the brew while preventing tea particles from seeping into the liquid. Over the years, tea filter paper materials have evolved from gauze, paper, nylon, PET, PVC, and PP to corn-based fibers.

Corn fiber, also known as polylactic acid (PLA) fiber, is derived from renewable plant resources like corn, potatoes, and agricultural straw. It offers excellent biocompatibility and biodegradability, antibacterial properties, and breathability. PLA fibers can be made into biodegradable non-woven tea bags and are also applicable in wet-process papermaking to create tea bags, coffee bags, filter paper, and other food packaging papers.

So, what are the main advantages of PLA fiber in wet-process papermaking?

1. Natural Material Safe for Food Contact

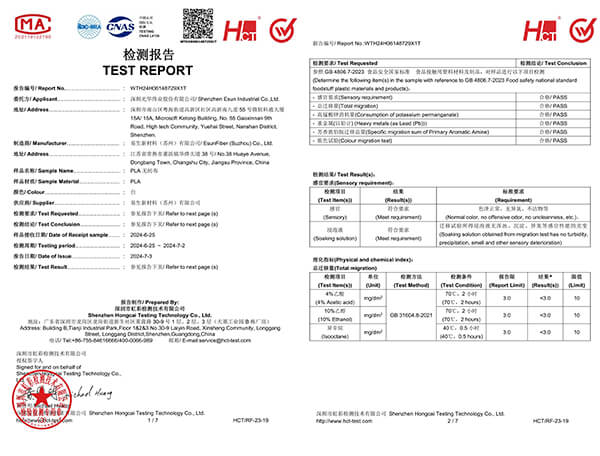

PLA fiber is sourced from renewable plant resources, and as a certified food-safe material, it is widely used for food, pharmaceuticals, and specific paper products for high-contact applications. For example, tea bags and coffee filter paper made from PLA can be directly placed in hot water without releasing plastic or harmful substances, making it safer for consumers.

As shown in the image, eSUN's PLA non-woven fabric has passed food-contact testing according to GB 4806.7-2023, "National Food Safety Standard for Plastic Materials and Products in Contact with Food." The test results for eSUN’s PLA non-woven fabric meet the required standards, making it a safe option for food packaging and providing consumers with peace of mind.

2. Biodegradability

The world consumes vast amounts of single-use tea bags daily, and traditional materials used in tea bags take a long time to decompose, putting a strain on ecosystems. However, tea bags or other products made from PLA fibers exhibit excellent biodegradability.

In specific natural environments (such as soil, silt, and seawater) with suitable temperature and humidity, PLA can be completely decomposed by microorganisms into carbon dioxide and water. Under industrial composting conditions (58°C, 98% humidity, and microbial activity), PLA products fully decompose into CO₂ and water within 3-6 months. In conventional landfill conditions, they degrade within 3-5 years.

3. Compatible with Wood Pulp and Other Natural Fibers

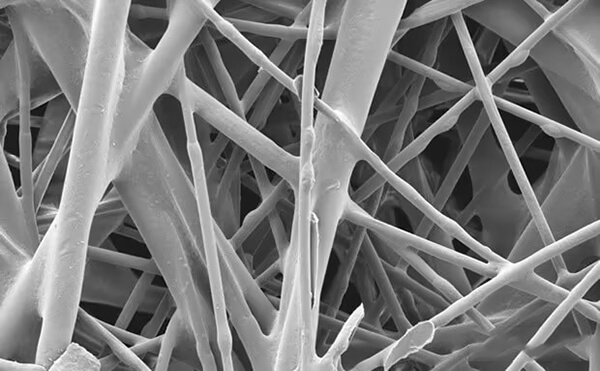

PLA fibers are often mixed with wood pulp fibers and nanofibers at specific ratios in pulp and papermaking. In these applications, PLA primarily serves as a bonding agent, strengthening the fibers when exposed to heat, creating a framework, and enhancing durability. By adjusting the pulp mixture and processing methods, PLA can meet diverse application needs.

4. Ultrasonic Thermal Bonding

When using PLA fibers in pulp and papermaking, ultrasonic thermal bonding is possible in the later production stages, which reduces labor costs, lowers production expenses, and increases efficiency.

5. Filtration Performance

Tea filter paper made from PLA fiber offers excellent filtration performance and high wet strength, effectively containing tea leaves and other solid particles while allowing the tea's flavor and aroma to infuse fully.

6. eSUN's Technological Innovations Drive Application Development

Standard PLA short-cut fibers are inherently hydrophobic and have limited dispersibility in water, making them prone to clumping. However, by adding custom-treated 3mm and 6mm ultrashort PLA fibers to the pulp, eSUN has significantly improved the dispersibility of PLA with other cellulose fibers, reducing fiber clumping and ensuring consistent paper quality.

Besides tea filter paper, PLA fibers can also be used in herbal medicine filter paper, coffee filter paper, and other food packaging papers.

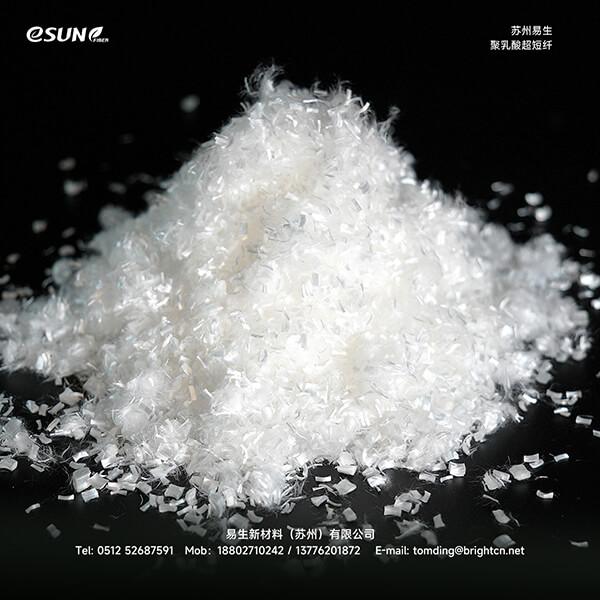

ESUN Fiber specializes in the research, production, and sales of PLA fiber and non-woven fabrics. Suzhou eSUN’s PLA short fiber products can be further classified into conventional single-component fibers, ultrashort fibers, bicomponent fibers, three-dimensional crimp fibers, colored fibers, profiled fibers, and functional fibers.

PLA Super Short Cut Staple can be used in wet-process papermaking, the product specification is 0.9~6D, length 3/6/12mm.

The application of PLA fibers in wet-process papermaking offers distinct environmental benefits and functional improvements. We welcome interested customers to inquire further as we explore innovative applications for PLA fiber together!