eSUNfiber to Showcase Bio-Based PLA Fiber Solutions at IDEA 2025 in the U.S.

As one of the most influential nonwovens industry events globally, the IDEA 2025 Nonwovens Exhibition will be held in Miami from April 29 to May 1.

Held every three years, the IDEA exhibition is widely regarded as an industry "bellwether." This year, eSUNfiber will present its bio-based polylactic acid (PLA) fiber nonwoven products and diverse applications, offering low-carbon, sustainable solutions for the nonwovens industry. Stay tuned!

1. PLA Air Through/Thermal Bonded Non-woven Fabric

Air through bonded products feature high bulkiness, excellent elasticity, soft hand feel, strong warmth retention, and good breathability and water permeability. With market development, air through bonded products with their unique characteristics have been widely used in disposable products such as baby diapers, adult incontinence pads, and women's hygiene product surfaces, as well as napkins, bath towels, and disposable tablecloths. Thicker products are used for cold-proof clothing, quilts, infant sleeping bags, mattresses, and sofa cushions. High-density thermal bonded products can be used for making filter materials, sound insulation materials, and shock absorption materials.

Example of eSUNfiber's PLA thin air through non-woven fabric

PLA thermal bonded non-woven fabric is soft, breathable, biocompatible, and hydrophilic, making it widely applicable for disposable medical and hygiene products such as medical masks, surgical gowns, and nursing pads. PLA thermal bonded non-woven fabric is also commonly used in packaging fields, such as food packaging bags, shopping bags, gift wrapping, and shoe box liners. Additionally, it serves as agricultural ground cover and plant protection material.

PLA non-woven fabric can be customized in various colors for medical consumables, such as blue and green, through pre-spinning processes or post-dyeing treatments.

Application example of PLA thermal bonded non-woven fabric: peach freshness preservation packaging bag

2.PLA Needled/Spunlaced Non-woven Fabric

eSUNfiber's PLA spunlaced non-woven fabric can be widely used in diaper and sanitary napkin topsheets/backsheets, makeup remover cotton, wipes, facial mask substrates, and other products. Moreover, due to its excellent biodegradability and breathability, it is also suitable for packaging applications such as food packaging and agricultural mulch.

PLA needled non-woven fabric can be extensively applied in geotextile materials as well as agriculture, animal husbandry, and horticulture. Taking short-fiber geotextiles as an example, they feature good flexibility and excellent water permeability, filtration, and isolation properties, suitable for slope treatment, roads, railways, dams, reclamation projects, and other applications requiring filtration, isolation, and drainage maintenance. In agriculture and horticulture, PLA needled non-woven fabric can be used to produce weed control fabric, hay wrapping fabric, and various specifications of planting bags.

Application of PLA needled non-woven fabric - weed control fabric

Application of PLA needled non-woven fabric - planting bag

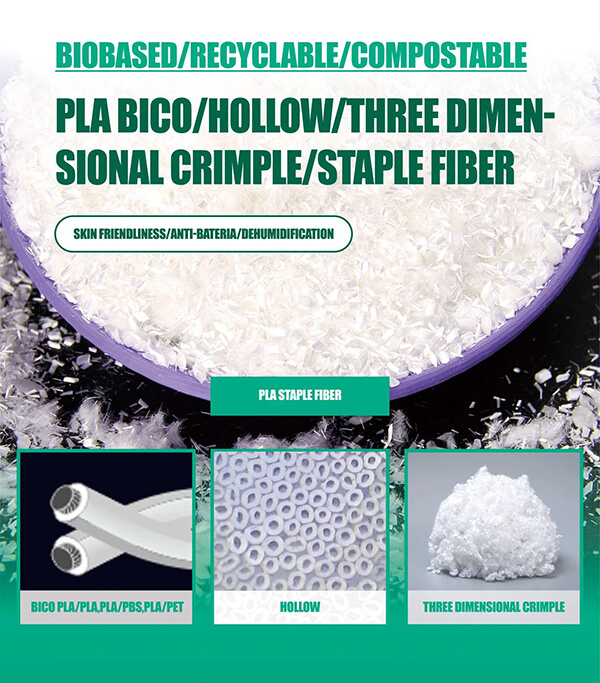

3.PLA Bicomponent Staple/Hollow Fiber/3D Crimped Staple/Staple Fiber

eSUNfiber primarily engages in the R&D, production, and sales of PLA fibers and non-woven fabrics. The company's products include various specifications of PLA staple fibers, filaments, yarns, and non-woven fabric products.

The company's PLA staple fiber products can be further subdivided into conventional staple fibers, super short cut staple, bicomponent staples, 3D crimped staples, colored spun yarns, profiled cross-section fibers, and functional fibers.

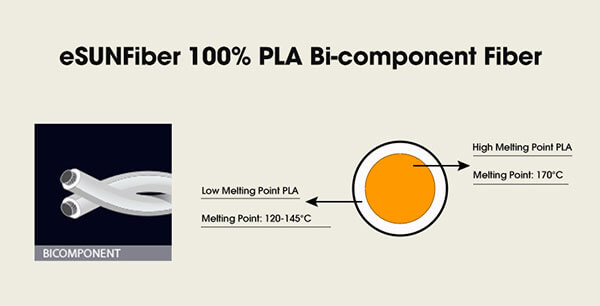

Among these, PLA bicomponent staple is the company's leading and distinctive product. eSUNfiber's PLA bicomponent staple, when combined with natural fibers such as hemp, cotton, and wool, or with regenerated cellulose fibers like viscose, lyocell, modal, and bamboo fiber, can replace conventional low-melt polyester fibers and ES fibers in the nonwovens field, achieving complete material degradability and providing more environmentally friendly and sustainable solutions for product upgrades. Additionally, PLA bicomponent staple combined with natural or regenerated fibers can also replace ES fibers to serve as bonding agents.

Non-woven fabrics have extremely wide application scenarios in daily production and life. Actively promoting the R&D and application of bio-based fiber materials contributes to the sustainable and healthy development of the economy and society. During the exhibition, both new and existing customers are welcome to visit and jointly explore innovative applications of PLA fibers and non-woven fabrics!