Hi everyone! I'm the newest member of the eSUN family –EsunFiber (Suzhou)! In the next few minutes, I'll give you a brief introduction about myself!

About Me and My Extended Family

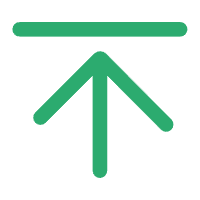

About eSUN

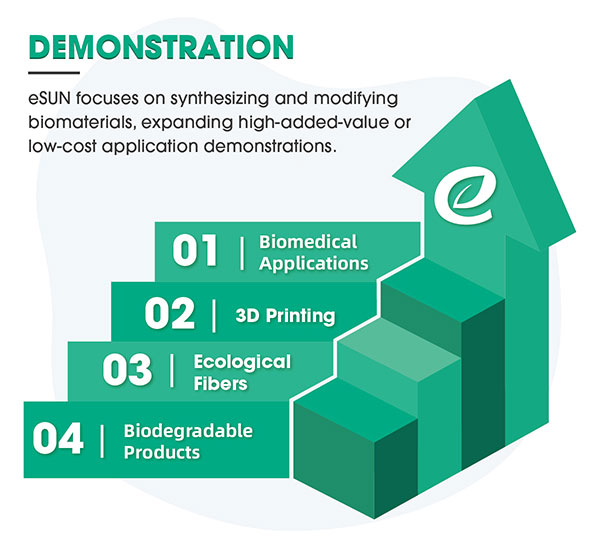

Shenzhen Esun Industrial Co., Ltd. (brand "eSUN") was established in 2002 and has been dedicated to the synthesis, modification, application, and recycling of PLA materials for over 20 years. eSUN is taking steps to establish a preliminary plan of applications in four fields: biomedical applications, 3D printing, ecological fibers, and biodegradable products. Adhering to the business philosophy of " Differentiated Positioning, Open Innovation," eSUN is committed to the industrial application of environmentally friendly materials. Through horizontal expansion and vertical extension, eSUN has completed our own technology, production facilities and marketing network layout on the green closed-loop industrial chain of polylactic acid. We have applied for more than 100 patents on the entire industrial chain, and obtained more than 60 authorizations (mainly invention patents). eSUN is a national high-tech enterprise, a national "Specialized, Refined, Differentiated, and Innovative" "little giant" enterprise, one of the top ten biodegradable enterprise in China, and a well-known biomaterial enterprise worldwide. eSun is the global leader in 3D printing materials and enjoys a reputation in the global 3D printing industry!

Introduction to eSUNFiber

As a member of eSUN, eSUNFiber is mainly engaged in the business of polylactic acid fiber non-woven fabrics and strives to become a leading enterprise of differentiated and functional polylactic acid fibers.

eSUNFiber leads the industry in PLA materials, PLA fiber, and nonwoven fabric. Among them, the dual-component PLA fiber is my flagship and distinctive product, achieving large-scale production and sales in developing single- and dual-component PLA fibers and differentiated products.

The Driving Force Behind eSUNFiber

As early as 2014, eSUN obtained a patent authorization for the "Method for Recycling Polylactic Acid to Prepare Refined-Grade Propylene Glycol." At the front end of the industry chain, eSUN has a 5,000 tons/year propylene glycol synthesis production facility in Xiaogan, Hubei. In addition to using lactic acid as raw material, recycled polylactic acid can also be used for propylene glycol production. At the back end of the industry chain, eSUNFiber can use propylene glycol as raw material to produce polylactic acid fiber. The two parties not only connect upstream and downstream in the industry chain but also complement each other's strengths at the technical level.

In addition, eSUN will support eSUNFiber in technical research and development, market expansion, operational management, funding, and talent, jointly promoting the development of polylactic acid fiber and application business.

My main business and key products.

Core Business

eSUNFiber focuses on developing and strategically expanding polylactic acid fiber and non-woven fabrics as main products.

Production Capacity

eSUNFiber has one 10,000 tons/year melt-spun polylactic acid fiber production line, one 1,000 tons/year polylactic acid hot air non-woven fabric production line, and three functional polylactic acid fiber production lines. Among them, the three functional polylactic acid fiber production lines have an annual capacity of 5,000 tons and can produce various differentiated products such as three-dimensional curled fibers, dual-component PLA fibers, profiled fiber, polylactic acid yarn, and solution-dyed polylactic acid fibers.

Main Products

ESUNFiber's main products include polylactic acid raw materials, fibers, and non-woven fabrics.

Introduction of eSUNFiber's Products

(1)Raw Material Category

Product Name | Specification | Application |

Fiber grade polylactic acid 1 | eSunAI6001 | Suitable for yarn |

Fiber grade polylactic acid 2 | eSunAI6002 | Suitable for staple fiber, non-woven fabric, etc. |

(2)Polylactic acid fiber category

Product Name | Specification | Application |

Polylactic acid staple fiber | Fineness:0.9-6dtex Length:3/6/12mm | Wet papermaking, flocking, etc. |

Polylactic acid single-component staple fiber | Fineness:1-6.67dtex Length:6-64mm | Yarn, non-woven fabric, etc. |

Polylactic acid dual-component staple fiber | Fineness:1.5-5dtex Length:6-64mm | Non-woven fabric, thermal bonding, filler, etc. |

Polylactic acid three-dimensional crimped staple fiber | Fineness:1.5-5dtex Length:38/51/64mm | Filling for clothing, home textiles and toys, etc. |

Polylactic acid filament yarn | DTY elastic filament, FDY fully drawn yarn, PLA monofilament | Fabric making, silk bundle, tea bag, etc. |

(3)Polylactic acid non-woven fabric category

Product Name | Specification | Application |

Thermal bonded non-woven fabric | Weight:20gsm-200gsm Width:7cm-220cm | Diaper sanitary napkin top layer bottom layer/mask wall cloth/product packaging, etc. |

Hot air non-woven fabric Weight | Weight:20gsm-45gsm Width:7cm-130cm | Diaper sanitary napkin top layer/hot air cotton, etc. |

Spunlace non-woven fabric | Weight:20gsm-100gsm Width:7cm-220cm | Diaper sanitary napkin top layer/makeup remover cotton/wet wipes/facial mask cloth, etc. |

Needle punched non-woven fabric | Weight:60gsm-800gsm Width:20cm-320cm | Clothing/suede fabric/ wall cloth/ carpet/ filter core, etc. |

Spunbond non-woven fabric | Weight:15gsm-150gsm Width:20cm-320cm | Mask/tea bag/ sand barrier/ protective clothing/ shopping bag/ geotextile, etc. |

Meltblown non-woven fabric | Weight:15gsm-45gsm Width:12cm-160cm | Mask filter layer/air purification cotton, etc. |

Polylactic Acid (PLA) fibers combine the advantages of natural fibers and chemically synthesized fibers. They possess a mild acidity similar to human skin and are skin-friendly, antibacterial, mite-resistant, and non-allergenic. PLA fibers also exhibit excellent durability, smoothness, breathability, and a glossy appearance. Additionally, textile products made from PLA fibers have the characteristic of self-extinguishing, enhancing safety in use.

Lactic acid fiber and its non-woven fabric can be widely used in sanitary materials, clothing fabrics, home textiles, toy stuffing, and medical supplies.

My Honors and Qualifications

Company Main Honors

The project "Efficient Bioproduction of Polylactic Acid and Technology for Fiber Preparation and Application," in which eSUNFiber participated, was awarded the First Prize for Scientific and Technological Progress by China National Textile And Apparel Council in 2023. The "Continuous Polymerization Melt Spinning Polylactic Acid Fiber," pioneered by eSUNFiber globally, was recognized as a "National Key New Product" by the Ministry of Science and Technology.

Important Patents and Certificates

eSUNFiber's polylactic acid fiber and non-woven fabric have successfully passed the compost degradation testing certification by DIN CERTCO (German Institute for Standardization).

Regarding product safety, eSUNFiber's polylactic acid non-woven fabric has passed skin sensitization tests, ensuring the product's safety performance. Additionally, through professional testing, eSUNFiber's polylactic acid fiber has demonstrated effective antibacterial properties.

In patent development, eSUNFiber obtained the patent technology for "A Method for the Preparation of Biodegradable Composite Fiber Non-adhesive Hollow Filter Rod" in 2021.

In the "Implementation Plan for the Quality Improvement and Upgrading of the Textile Industry (2023-2025)" jointly issued by the Ministry of Industry and Information Technology, the National Development and Reform Commission, the Ministry of Commerce, and the State Administration for Market Regulation, various bio-based fibers such as polylactic acid fiber, Lyocell fiber, and bio-based polyamide fiber are listed as crucial breakthrough directions in technology. The development of bio-based materials, the promotion of research and development, and the application of polylactic acid fiber will contribute to the green growth of the textile industry, reduce pollution, lower energy consumption, and achieve "carbon peak and carbon neutrality."

In the future, with the continuous support of eSUN, eSUNFiber will remain committed to the development of polylactic acid fiber and non-woven fabric, injecting the " eSUN" strength into the green growth of the textile industry.

Exhibition Invitation

The 2024 China Yarn Expo Spring is scheduled to be held from March 6th to 8th at the National Exhibition and Convention Center (Shanghai).

As a leading global trading platform for a comprehensive range of fiber and yarn products, Yarn Expo Spring is the premier launchpad for new technologies, materials, and products. It stands as an authoritative and professional platform for showcasing the latest trends in fiber and yarn and disseminating information on the industry's cutting-edge developments. Yarn Expo Spring is set to sound the 'assembly call' for innovation in the upstream textile sector, attracting the attention of the global textile community.

At that time, eSUNFiber will showcase a diverse range of biodegradable fibers and non-woven fabric products at Booth J96 in Hall 8.2! We welcome everyone to visit and exchange ideas!