Polylactic Acid(PLA) Introduction

Polylactic acid (PLA) is made from renewable plant resources through biotechnological processing. Products from this material can be degraded into water and carbon dioxide under composting conditions after disposal. PLA has a wide range of applications; it can be processed as plastic or fiber, making it an integrated material for both fiber and plastic.

Polylactic Acid (PLA) fibers combine the advantages of natural fibers and chemically synthesized fibers. They possess a mild acidity similar to human skin and are skin-friendly, antibacterial, mite-resistant, and non-allergenic. PLA fibers also exhibit excellent durability, smoothness, breathability, and a glossy appearance. Additionally, textile products made from PLA fibers have the characteristic of self-extinguishing, enhancing safety in use.

PLA fiber category

Commonly used polylactic acid fibers can be divided into two main categories: polylactic acid short fibers and polylactic acid filaments.

1. PLA Short Fiber

PLA Short Fiber is a fiber product with certain mechanical properties such as strength and elasticity. Its product types include pure spun products, as well as blended products with cotton, wool, linen, lyocell, and modal fibers.

Image | eSUN conventional single-component fibers

eSUN Fiber's PLA short fiber products can be further subdivided into conventional single-component fibers, ultra-short fibers, bi-component fibers, three-dimensional crimped fibers, colored spun yarns, special cross-section fibers, functional fibers, etc.

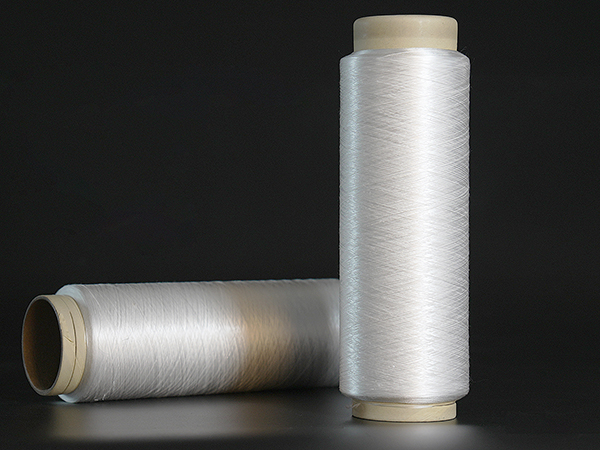

2.PLA Filament Yarn

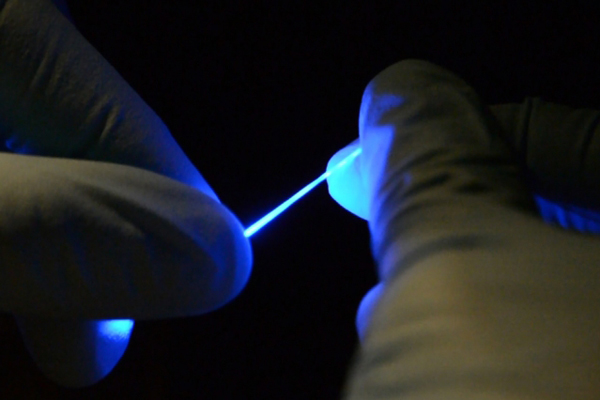

PLA filament yarn is a collection of fibers formed by stretching, twisting, or deforming multiple long monofilaments. A single strand of filament contains dozens of monofilaments, which is known as PLA composite filament. This can be spun into differentiated PLA fibers. At the same time, it also includes PLA monofilament, which, due to its unique properties, is widely used in fields such as medical sutures, fishing, and tea bags.

Image | eSUN PLA filament yarn

Performance of PLA Fiber

In addition to good mechanical properties and smooth breathability, PLA fibers have biodegradability and biocompatibility, which are not found in general chemical fibers.

1. Mechanical Properties

According to test results, the breaking strength of PLA fibers is 3.2~4.9cN/dtex, higher than natural cotton fibers. The dry-state breaking elongation rate is similar to nylon and wool, and the elongation rate increases in the wet state, indicating that PLA fiber products have the advantages of high strength and good extensibility.

2.Biodegradability

Under average temperature and humidity, PLA fibers and their products are stable. When in a natural environment with specific temperature and humidity (such as sand, silt, seawater), microorganisms will completely degrade PLA into carbon dioxide and water. If PLA fibers are buried in the soil, the natural degradation time is 2~3 years; if PLA fibers are mixed and buried with organic waste, they will decompose in a few months.

PLA waste products can be completely decomposed into carbon dioxide and water in industrial composting conditions (temperature 58°C, humidity 98%, and microbial conditions) within 3-6 months, which has a perfect environmental effect.

eSUN’s PLA Fiber has passed the German DIN compostable certification and the American BPI degradable certification.

3.Biocompatibility, Anti-allergy

PLA comes from lactic acid, which is an endogenous substance in the human body, and the pH value of the fiber is almost consistent with that of the human body, giving PLA fiber good biocompatibility, excellent skin affinity, non-allergenicity, and good product safety performance, thus it can also be widely applied in the biomedical field.

4.Antibacterial and Anti-mite, Anti-mold and Anti-odor

The surface of PLA fiber exhibits the weak acidity of lactic acid, giving it natural antibacterial properties, effectively inhibiting the growth of mites, and providing anti-mold and anti-odor effects.

5.Wearability

① Drape: PLA fiber has a low initial modulus and a small drape coefficient, giving the fabric good draping properties.

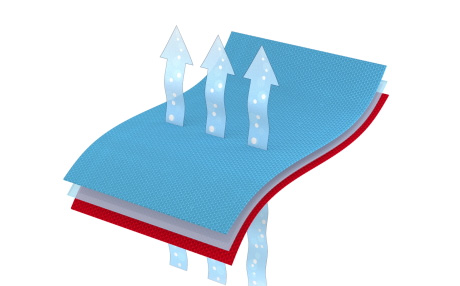

② Moisture Absorption and Breathability: PLA fiber has poor moisture absorption but good breathability.

③ Crease Recovery: PLA fiber has an elastic recovery rate of up to 93% when stretched by 5%, so pure PLA fiber fabrics have good crease recovery.

④ Abrasion Resistance and Pilling: PLA fiber has slightly better abrasion resistance than polyester, but the fabric has pilling phenomena.

⑤ Good Thermal Insulation.

PLA fiber is a lightweight fiber that can quickly return to dryness after being dampened or wetted. PLA fiber products can perform different functions in different seasons. In winter, the thermal insulation performance is better than cotton and polyester fibers; in summer, the moisture permeability and water diffusion are excellent, sweat-absorbing and quick-drying, and body heat can be quickly taken away through evaporation.

6.Other Properties

① Good UV Resistance.

The molecular structure of PLA fiber contains a large number of C—C and C—H bonds, which generally do not absorb light with a wavelength less than 290nm. Therefore, the ultraviolet rays reaching the Earth have almost no effect on PLA fibers, and PLA fiber products have good UV resistance.

② Self-extinguishing, Low Smoke, Non-toxic.

PLA fiber is not easily flammable, self-extinguishes upon removal from fire emits no black smoke or toxic gases and is safe to use.

Applications of Polylactic Acid Fiber

PLA can be made into short fibers, filaments, non-woven fabrics, etc., and is widely used in industries such as sanitary materials, clothing fabrics, home textiles and toy fillings, medical supplies, etc.

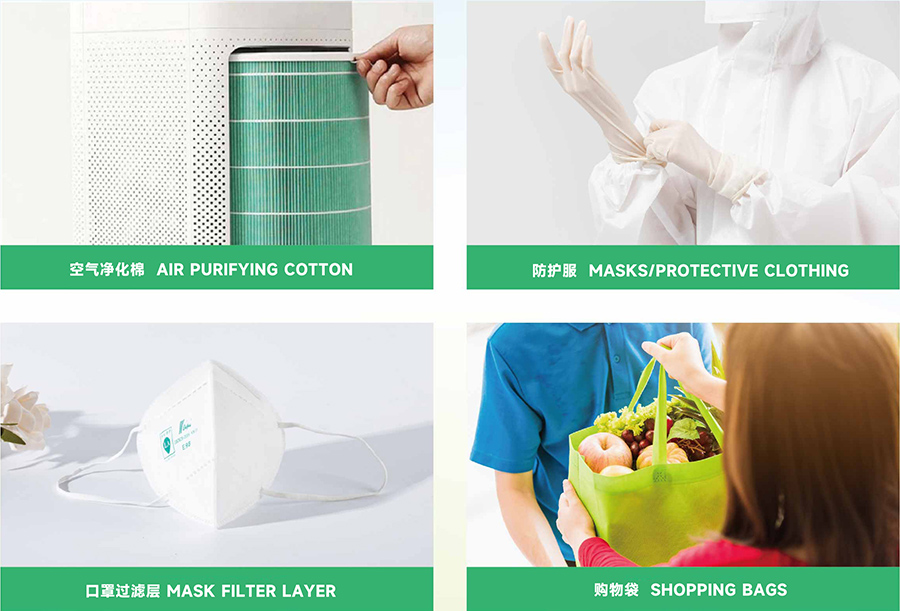

1. Sanitary Materials

PLA non-woven fabric has a smooth surface, does not absorb moisture, and has better fluidity, dryness, biocompatibility, and non-allergenicity, making it more suitable for people prone to allergies. It can be widely used in related fields of sanitary materials, such as the surface layer, diversion layer, and bottom layer of sanitary napkins and paper diapers, makeup remover cotton, wet wipes, face towels, membrane cloth, and other disposable sanitary products.

PLA fiber can meet the antibacterial requirements of disposable medical and sanitary products and solve the "white pollution" problem caused by disposable medical and sanitary products due to its biodegradability.

2.Apparel Fabrics

PLA fiber has physical properties similar to polyester/polyester materials, can be shaped, has good strength good dimensional stability, does not irritate the skin, is easy to wash and dry, and can also be functionalized by changing the process during spinning and adding other materials, such as moisture absorption and perspiration, UV protection, etc., thus developing uniquely advantageous apparel fabrics.

① Sports and Leisure Clothing — DTY low-elastic yarn knitted fabric (POLO shirts, T-shirts, etc.)

② Underwear — Interwoven, blended, changing the tradition of not using polyester fibers in underwear, making underwear retain better shape and safety.

③ Children's Clothing: Non-allergenic, skin-friendly, and flame-retardant is one of the elements of modern children's clothing.

④ Other Applications.

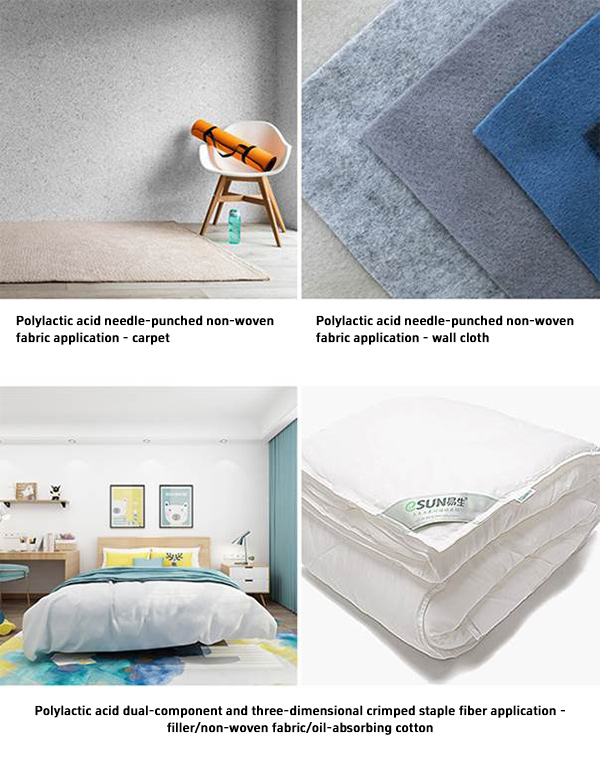

3. Home Textiles and Toy Fillings

①Fillings for quilts, pillows: Represented by hollow PLA short fibers, it can be pure PLA or blended with other fibers, replacing existing polyester-related fillers.

②Bedding fabrics (interwoven, blended, etc.): Can fully utilize its advantages of being skin-friendly, non-irritating, non-allergenic, overcoming the shortcomings of polyester/cotton fabrics, having better dimensional stability than all-cotton fabrics, and being easy to wash, dry, and care for.

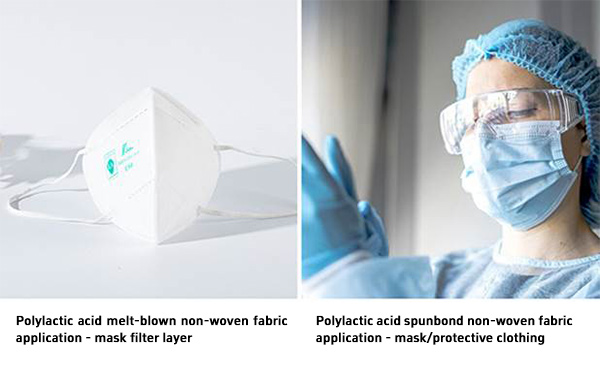

4.Medical Supplies

Masks, protective clothing, medical gauze, bandages, sheets, and high-end antibacterial products, etc.

5.Other Applications

Packaging materials, agricultural cloths, sand barriers, filter bundles, decorative board adhesives, etc.

PLA fiber is known as "eco-fiber," its raw materials are sourced from renewable plant resources, which will reduce the consumption of non-renewable resources such as petroleum in the textile industry to a certain extent, and decrease the emission of greenhouse gases. Moreover, the production process of PLA fiber is also more low-carbon and environmentally friendly. From raw materials to waste, it can be decomposed into carbon dioxide and water in soil or seawater through microbial action, and it does not emit toxic gases when burned, thus not causing pollution.

EsunFiber's parent company, Shenzhen Esun Industrial Co., Ltd. (brand "eSUN"), has mastered the chemical recycling technology of PLA and has industrialized it, which can establish a green closed-loop industrial chain for the production of PLA fiber products, further realizing the efficient recycling and utilization of resources.

PLA fiber has tremendous development potential in various industries and fields, such as textiles, agriculture, and tissue engineering. As many countries increasingly focus on developing biobased materials, PLA fiber is set to become one of the key products in the field of textiles and non-woven fabrics in the 21st century.

EsunFiber focuses on developing and strategically expanding polylactic acid fiber and non-woven fabrics as main products. EsunFiber has one 10,000 tons/year melt-spun polylactic acid fiber production line, one 1,000 tons/year polylactic acid hot air non-woven fabric production line, and three functional polylactic acid fiber production lines. Among them, the three functional polylactic acid fiber production lines have an annual capacity of 5,000 tons and can produce various differentiated products such as three-dimensional curled fibers, dual-component PLA fibers, profiled fiber, polylactic acid yarn, and solution-dyed polylactic acid fibers.

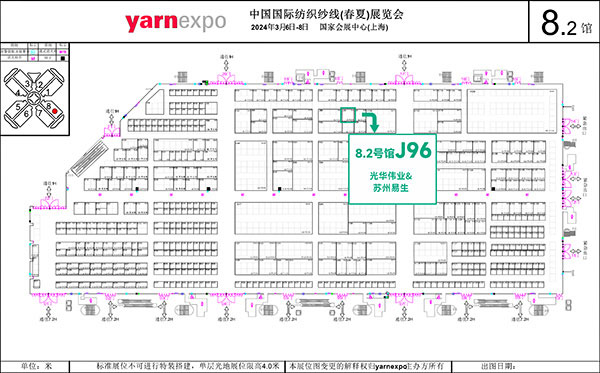

Exhibition Invitation

The 2024 China Yarn Expo Spring is scheduled to be held from March 6th to 8th at the National Exhibition and Convention Center (Shanghai).

At that time, EsunFiber will showcase a diverse range of biodegradable fibers and non-woven fabric products at Booth J96 in Hall 8.2! We welcome everyone to visit and exchange ideas!