1.About PLA Short Staple

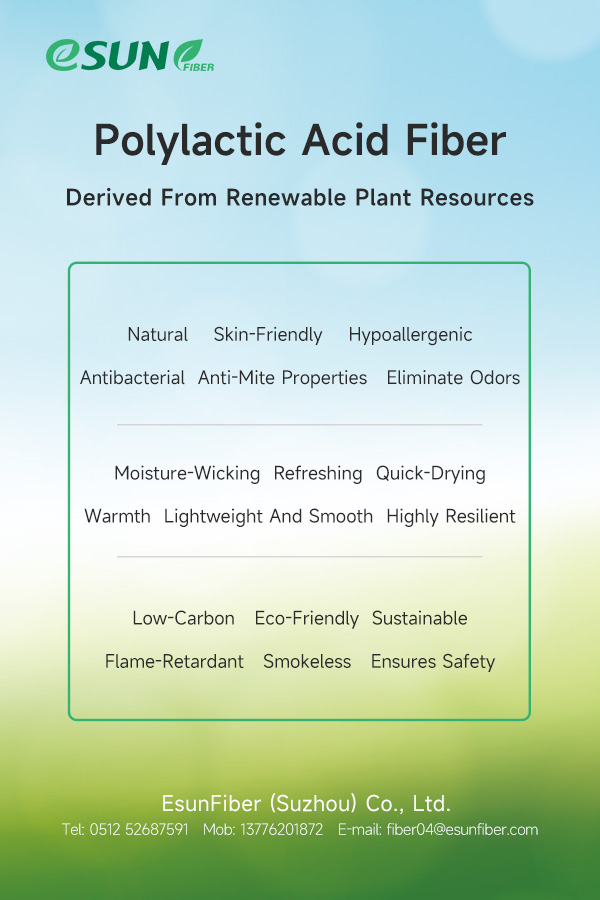

Polylactic acid (PLA) short staple is a biobased and biodegradable fiber made from renewable resources, such as corn starch. Due to its environmental characteristics and diverse application potential, PLA short staple has been promoted and applied in various fields.

Image | eSUN conventional single-component fibers

2.PLA Short Staple Category

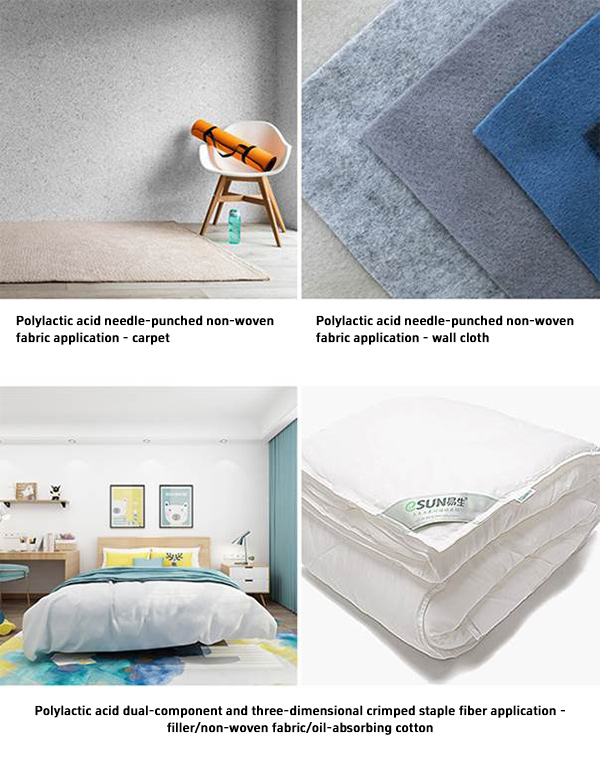

PLA Short Staple is mainly divided into three categories according to their use: for spinning and making yarn, for filling, and for non-woven applications. Spinning and thread-making are the primary uses of PLA Short Staple. Filling mainly refers to using short fibers as filling materials for home decoration and clothing insulation, such as bedding, cotton clothes, sofa furniture, and plush toys. Non-woven is an extension of the application of short fibers and has developed rapidly in recent years. The application of non-woven fabric is quite extensive; for instance, spun lace non-woven fabric is mainly used in wet wipes, medical fields, etc. Needle-punched non-woven fabric can be applied to geotextiles, leather base fabric, felt base fabric, and other related engineering fields. In addition, hot-rolled, hot-air, non-woven fabric is used in packaging, sanitary materials, and other areas.

eSUN Fiber's PLA short staple products can be further subdivided into conventional single-component fibers, ultra-short fibers, bi-component fibers, three-dimensional crimped fibers, colored spun yarns, special cross-section fibers, functional fibers, etc.

3.Introduction of eSUN Fiber's Products

Product Name | Specification | Application |

Polylactic acid staple | Fineness:0.9-6D Length:3/6/12mm | Wet papermaking, flocking, etc. |

Polylactic acid single-component staple fiber | Fineness:1-6D Length:6-64mm | Yarn, non-woven fabric, etc. |

Polylactic acid dual-component staple fiber | Fineness:1.5-5D Length:6-64mm | Non-woven fabric, thermal bonding, filler, etc. |

Polylactic acid three-dimensional crimped staple fiber | Fineness:1.5-5D Length:38/51/64mm | Filling for clothing, home textiles and toys, etc. |

4.eSUN Fiber PLA Short Staple Application

① Apparel Fabrics: Pure spinning or blending, mixed with various other fibers such as cotton, linen, silk, wool, viscose, and lyocell, can produce different clothing fabrics.

② Disposable Sanitary, Medical Supplies, and Packaging Materials: PLA short staple can also be widely used in the packaging field and the direction of disposable consumer goods, especially sanitary materials (such as urine pads, diapers, sanitary napkins, etc.).

③ Filling for Quilts, Cotton Jackets, and Toys: Represented by three-dimensional crimped PLA short staple, it can be pure PLA or mixed with other fibers, replacing existing polyester-related fillers.

As a new eco-friendly material, PLA fiber has tremendous development potential in multiple industries and fields, such as textiles, agriculture, and sanitary materials.

EsunFiber focuses on developing and strategically expanding polylactic acid fiber and non-woven fabrics as main products. EsunFiber has one 10,000 tons/year melt-spun polylactic acid fiber production line, one 1,000 tons/year polylactic acid hot air non-woven fabric production line, and three functional polylactic acid fiber production lines. Among them, the three functional polylactic acid fiber production lines have an annual capacity of 5,000 tons and can produce various differentiated products such as three-dimensional curled fibers, dual-component PLA fibers, profiled fiber, polylactic acid yarn, and solution-dyed polylactic acid fibers.

Welcome interested customers to consult and discuss cooperation!