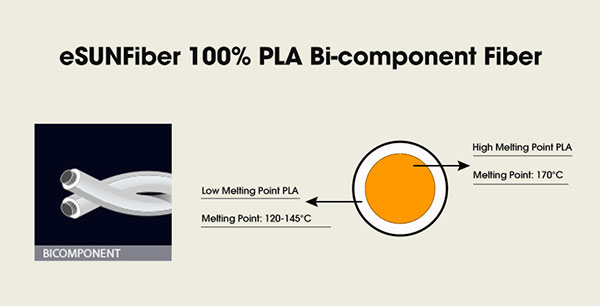

Composite fibers are categorized into two main types based on the number of components: bi-component fibers and multi-component fibers. Bi-component fibers can be further divided into side-by-side, sheath-core, sea-island, and segmented types, depending on the relationship between the two components within the fiber. They are made by composite spinning of two or more polymers with different molecular weights and properties.

Ⅰ. eSUNFiber PLA Bi-component Staple Introduction

Image | eSUNFiber PLA Bi-component Staple

Product Specification:Fineness1.5-5D/Length6-64mm

PLA bi-component staples are a leading and distinctive product of eSUNFiber, with mature production technology and stable product quality. The product is a bi-component skin-core structure composite fiber made of 100% polylactic acid, where the sheath component is made of low melting point polylactic acid with good softness, and the core component is made of high melting point polylactic acid with high strength.

After heat treatment, part of the sheath layer of the PLA bi-component staple melts and acts as an adhesive, while the rest retains the fiber state. The fibers are interconnected, forming a non-woven fabric body without adhesives, and it also features a low thermal shrinkage rate.

The absence of chemical adhesives prevents the introduction of allergens and irritants, maintaining the natural advantages. The resulting materials and products are non-toxic, non-irritating, more skin-friendly, and environmentally friendly, making them popular among consumers.

PLA bi-component staples have a wide range of processing suitability. The main non-woven fabric processing methods, such as CALENDER, THROUGH-AIR, NEEDLE PUNCH, WET LAID, AIR-LAID, and SPUNLACE, can be used. These fibers are particularly suitable for producing sanitary materials, thermal insulation fillers, filter materials, etc., through the hot air penetration. They are also the best choice for all degradable, non-woven fabrics, glue-free cotton, and natural composite board bonding materials.

Ⅱ.eSUNFiber PLA Bi-component Staple Applications

1.Non-woven Fabric Applications, such as sanitary materials, packaging materials, medical supplies

Due to its softness, low-temperature processability, non-toxicity, non-irritation, and lightweight, bi-component PLA fiber is ideal for manufacturing sanitary pads, diapers, and other hygiene products.

PLA fiber has good biocompatibility, dryness, breathability, antibacterial and deodorizing properties, and biodegradability. On one hand, it meets the requirements for skin-friendly comfort and odorless antibacterial properties for medical and sanitary products. On the other hand, its biodegradability addresses the "white pollution" caused by disposable medical and hygienic products.

PLA bi-component staple is further processed into through-air, hot-rolling, needle punch, spun lace, and non-woven fabrics. It is applied to fast-moving consumer goods, packaging materials, and medical supplies.

Application Examples | Disposable Sanitary Products

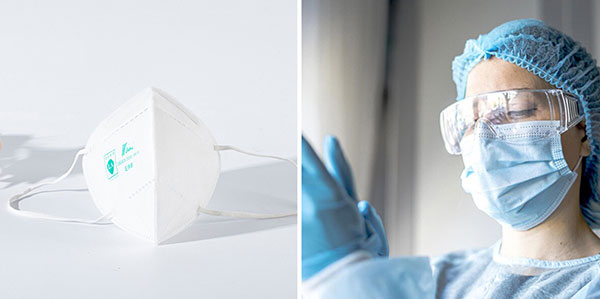

Application Examples | Medical Supplies (Masks, Protective Clothing)

2.Thermal bonding applications

PLA Bi-component Staple is an ideal thermally bondable fiber, mainly used for the thermal bonding process of non-woven fabrics. This is a form of "point bonding" rather than "area bonding," thus the product possesses characteristics such as bulkiness, softness, high strength, oil absorption, blood absorption, and other factors.

Using PLA bi-component fiber for thermal bonding has the advantage of achieving adhesion without the need for adhesives. This not only avoids the need to handle excess components, making it environmentally friendly and in line with the concept of sustainable development, but it also allows for a wide range of fabric properties and aesthetics.

When bi-component PLA fiber is mixed with natural fibers, man-made fibers, pulp, etc., and processed through dry or wet non-woven fabric processes, it significantly enhances the strength of the non-woven fabric. It also imparts dryness, breathability, antibacterial, and deodorizing effects to natural fiber products, complementing their advantages and significantly improving the performance of non-woven fabrics. This composite material is also widely used in disposable sanitary materials (including diapers, sanitary pads, underpads, healthcare mattresses, etc.) for top layers, bottom layers, and wrapping materials).

PLA bi-component staple can also be applied to filter materials, gardening household materials, insulation materials, adsorption materials, packaging materials, rigid fiberboards, automotive wall materials, and padding, etc.

3.Fillers

Utilizing the difference in properties of the two components, the shrinkage difference is generated after stretching and heat treatment, causing the fibers to produce permanent three-dimensional natural curls. Therefore, it can be widely used as fillers, such as flakes, stuffed toy fillings, mattresses, etc.. Its natural drying, antibacterial, and deodorizing properties have wide application advantages in baby products, elderly products, and pet products.

Ⅲ.Qualifications and Advantages of eSUNFiber

eSUNFiber's continuous polymerization melt direct spinning bi-component fiber production line and short-fiber non-woven fabric production line are specialized demonstration lines for PLA fiber and its applications. They have achieved a breakthrough from nothing, solving many problems in manufacturing and using PLA bi-component staple. The entire production process of non-woven fabric does not require any chemical adhesives or other additives, realizing a green alternative to petroleum-based polymers with both environmental and economic benefits.

On August 21, 2021, the Ministry of Industry and Information Technology of the People's Republic of China issued the FZ/T 52058-2021《Low melting point polylactide (LMPLA) / polylactide (PLA) bicomponent staple fiber》textile industry standard. This standard was primarily drafted by eSUNFiber (formerly HI-TECH CHANGJIANG PLA CO., LTD.) and was officially implemented in February 2022.

Currently, eSUNFiber has one 10,000 tons/year melt-spun polylactic acid fiber production line, one 1,000 tons/year polylactic acid hot air non-woven fabric production line, and three functional polylactic acid fiber production lines. Among them, the three functional polylactic acid fiber production lines have an annual capacity of 5,000 tons and can produce various differentiated products such as three-dimensional curled fibers, dual-component PLA fibers, profiled fiber, polylactic acid yarn, and solution-dyed polylactic acid fibers.

In January 2024, Shenzhen Esun Industrial Co., Ltd. (brand "eSUN") and Beijing Institute of Fashion Technology officially signed an agreement on the "PLA Side-by-Side Composite Fiber Cooperation Project." Both parties will use eSUNFiber as a base to explore the production and application of PLA three-dimensional crimped fibers. PLA three-dimensional crimped fibers are fluffy and elastic, with good moisture conduction and breathability, and are widely used in filling and insulation fibers, among other fields.

The industrialization and promotion of green fibers and products is one of the eight key projects implemented by the textile industry during the "14th Five-Year Plan" period. The research and development and application expansion of bio-based PLA fibers are of great significance for promoting the green development of the textile industry. eSUNFiber will continue to devote itself to the PLA fiber non-woven fabric business and welcomes interested customers to inquire and discuss cooperation.