Polylactic acid (PLA) air-through non-woven fabric is mainly made from short fibers with a sheath-core structure, that is, polylactic acid heat-bondable fibers. After the short fibers are carded into a web, hot air from drying equipment penetrates the fiber web, causing the sheath layer to partially melt and adhere, forming a material with particular strength and thickness.

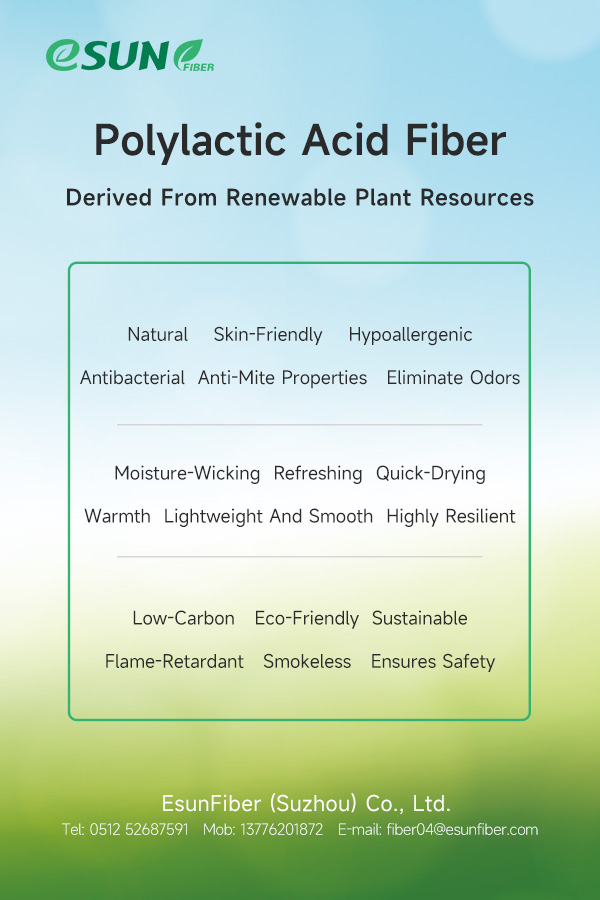

During the production process of PLA Air Through Non-woven Fabric, there is no need to add extra chemical adhesives. The sheath-core structured fibers have a low melting point in the sheath layer and good softness, while the core layer has a high melting point and strength, giving the non-woven fabric its fluffy and soft characteristics. Coupled with biodegradability, antibacterial properties, good biocompatibility, high resilience, and low moisture regain of polylactic acid non-woven fabric, it can be widely used in sanitary materials, thermal insulation filling materials, filter materials, etc.

eSUNFiber Air Through Non-woven Fabric

eSUNFiber's PLA Air through Non-woven Fabric products have a weight range of 20gsm-45gsm and can be used in the top and bottom layers of products such as diapers, sanitary napkins, as well as for air through cotton, etc.

Image | eSUNFiber PLA Thin Air Through Non-woven Fabric Product Example

The hot air bonded products have high fluffiness, good elasticity, a soft touch, strong warmth retention, and good breathability and water permeability. With the development of the market, hot air bonded products are widely used in the manufacture of disposable products, such as baby diapers, adult incontinence pads, women's sanitary fabrics, as well as napkins, bath towels, disposable tablecloths, etc.; thick products are used to make cold-proof clothing, quilts, baby sleeping bags, mattresses, sofa cushions, etc. High-density hot-melt bonded products can be used to make filter materials, sound insulation materials, shock absorption materials, etc.

Polylactic acid fibers and non-woven fabric products have good biocompatibility, dry and breathable properties, antibacterial and deodorizing properties, and biodegradability. On one hand, they can meet the requirements of medical and sanitary products for skin-friendly comfort and antibacterial odorlessness, suitable for people prone to allergies. On the other hand, their biodegradability solves the problem of "white pollution" caused by disposable medical and sanitary products.

In addition, polylactic acid bicomponent short fibers are eSUNFiber's leading and characteristic products, with mature production technology and stable product quality. The bicomponent PLA Air Through Non-woven Fabric is developed and produced by eSUNFiber based on its own developed annual production line of 10,000 tons of polymer melt direct-spun bicomponent polylactic acid fibers and a yearly production line of 1,500 tons of PLA hot air hot-rolled non-woven fabric. Significant progress has been made in continuous polymerization technology and equipment R&D, bicomponent polylactic acid fiber production technology equipment development, and low melting point fiber rapid carding technology and equipment development.

The processing methods of products, such as non-woven fabrics made from bicomponent polylactic acid fibers, are more flexible. The processing of air through non-woven fabric is achieved by melting the low melting point part of the PLA on the surface while maintaining the stable form of the high melting point inner layer, giving the product an excellent hand feel and fluffy texture without deformation. In addition to being used for bio-based protective materials such as masks, protective clothing, and surgical gowns, bicomponent PLA Air Through Non-woven Fabric can also be used for garden crop protection, disposable sanitary products, flower wrapping cloth, face towels, etc.

About eSUNFiber

eSUNFiber focuses on developing and strategically expanding polylactic acid fiber and non-woven fabrics as main products. eSUNFiber has one 10,000 tons/year melt-spun polylactic acid fiber production line, one 1,000 tons/year polylactic acid hot air non-woven fabric production line, and three functional polylactic acid fiber production lines. Among them, the three functional polylactic acid fiber production lines have an annual capacity of 5,000 tons and can produce various differentiated products such as three-dimensional curled fibers, dual-component PLA fibers, profiled fiber, polylactic acid yarn, and solution-dyed polylactic acid fibers.

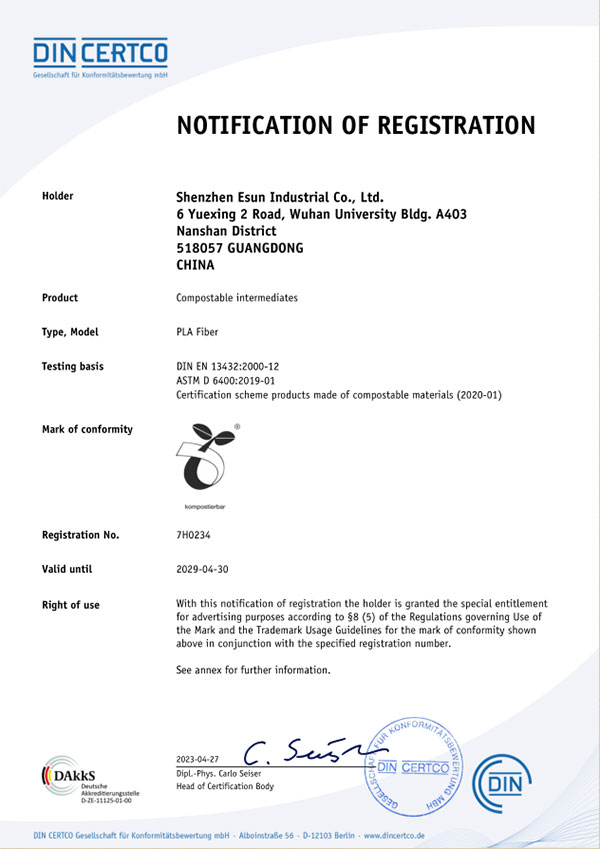

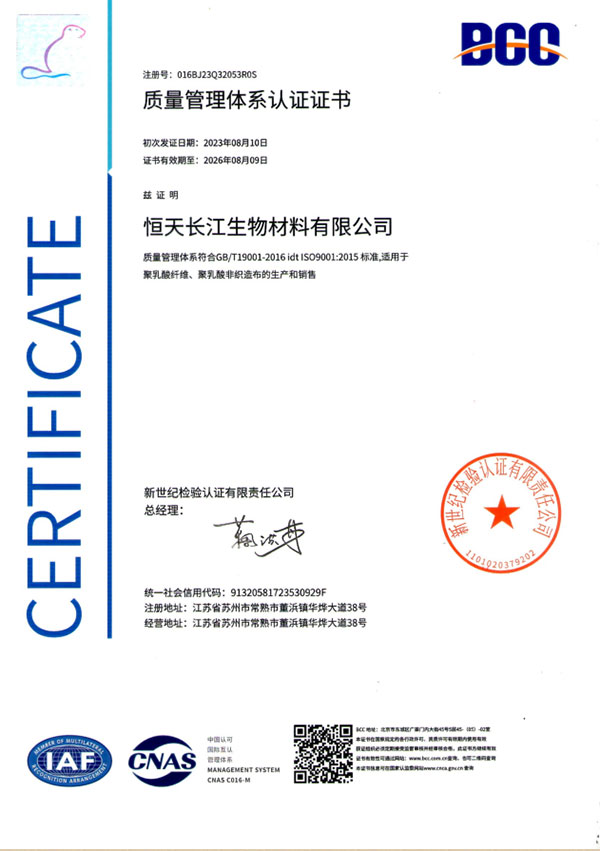

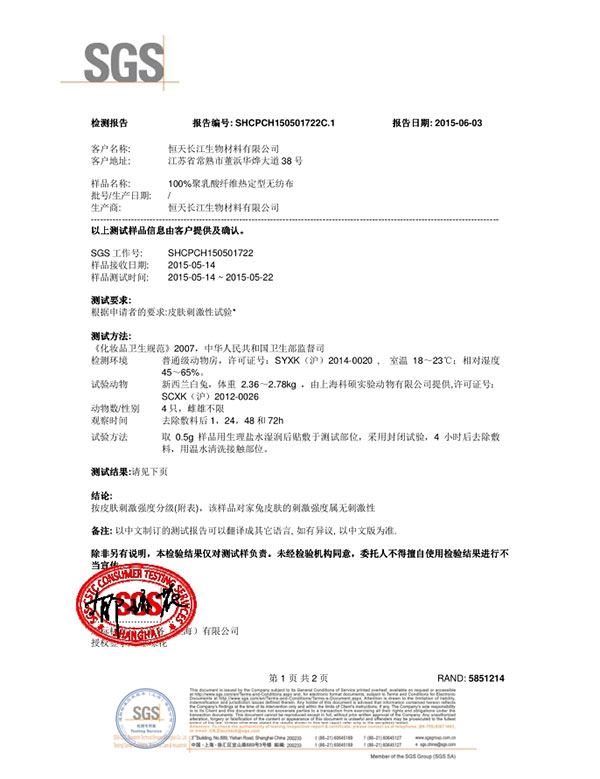

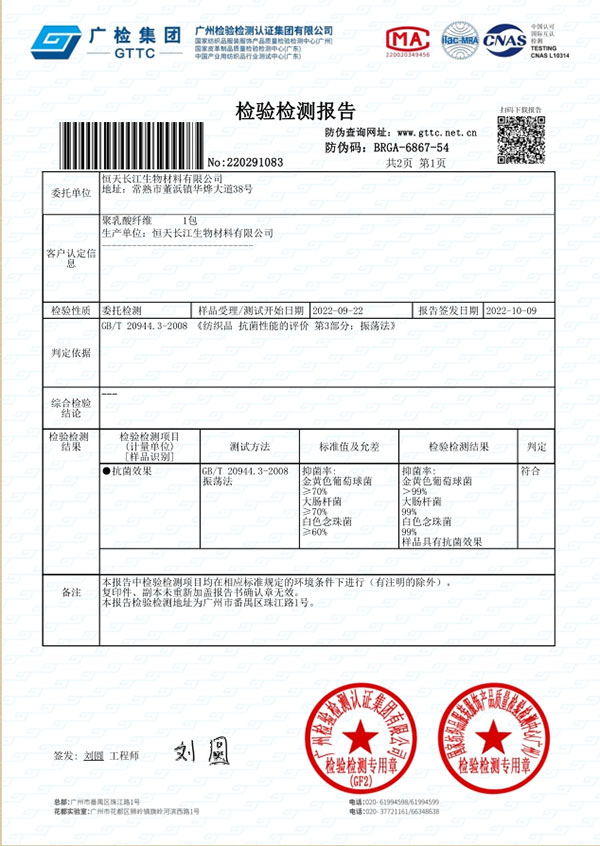

eSUNFiber's polylactic acid fibers and non-woven fabrics have successfully passed the compost degradation test certification by DIN CERTCO (German Standards Association Certification Center). In terms of product safety, eSUNFiber's PLA non-woven fabric products have passed skin sensitization tests, ensuring product safety performance! Additionally, after testing by professional institutions, eSUNFiber's polylactic acid fibers have shown good antibacterial effects.

Welcome you inquire and discuss cooperation with us!