Quilts, pillows, cushions, stuffed toys... These are all items frequently used in daily life, or rather, items that are in close contact with the human body.

When selecting home textiles, in addition to considering the fabric, understanding the types and characteristics of the filling materials can help in choosing the right products, thereby enhancing the comfort of life.

Home textile filling fibers generally refer to the filling materials used for manufacturing home goods such as quilts, pillows, and cushions. Common filling materials include natural fibers (such as down and cotton), synthetic fibers (such as polyester fiber), and blended materials. Natural fibers usually provide good breathability and comfort, while synthetic fibers are more durable.

In the modern home textile field, we are constantly seeking materials that perfectly combine comfort and environmental sustainability. This article will mainly introduce the application of PLA fiber in home textile fillings.

One of the major concerns for users in home textile applications is the issue of dust mites! PLA fiber, as an eco-friendly fiber, has significant advantages in this regard.

1、Antibacterial, Anti-Mite, Anti-Mold, and Odor Removal

The anti-mite mechanism of PLA fiber lies in its surface's lactic acid weak acidity, which has natural antibacterial properties, effectively inhibiting the growth of dust mites, while also offering anti-mold and odor-resistant benefits.

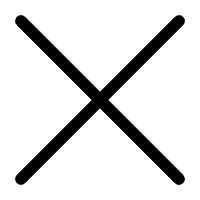

2、Natural Skin-Friendliness and Anti-Allergic

PLA is derived from lactic acid, an endogenous substance in the human body. PLA fiber has excellent biocompatibility, making it highly skin-friendly and non-allergenic.

3、Biodegradability and Recyclability

Compared to other synthetic fibers, the biggest advantage of PLA fiber is that it easily decomposes in the natural environment. The decomposition produces carbon dioxide and water, which do not pollute the environment and can re-enter the ecological cycle through the photosynthesis of green plants.

In addition, in terms of related physical properties, PLA fiber also performs well! Filling fibers usually require a certain level of resilience to maintain the product’s fluffiness and aesthetic appearance. In specific applications, PLA fiber has certain advantages:

1.Resilience and Smoothness

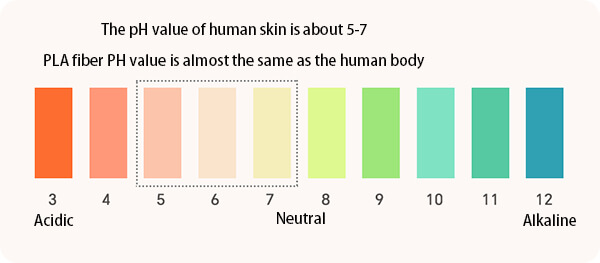

The macromolecular structure of PLA fiber gives it good resilience. When stretched by 5%, the elastic recovery rate of PLA fiber is as high as 93%. eSUNFiber has developed a PLA Three-dimensional Crimped Staple for home textile filling applications, which boasts excellent Resilience.

2.Moisture Regain and Breathability

PLA fiber is a lightweight fiber that, even when damp or soaked in water, can quickly return to a dry state. Additionally, it has good breathability.

3.Flame Retardant, Low Smoke, and Non-Toxic

PLA fiber is not easily flammable and self-extinguishes when removed from fire, with no black smoke or toxic gas emissions, ensuring high safety in use.

eSUNFiber’s PLA short fiber can be used as a filling material for home textiles and clothing insulation, such as bedding, padded jackets, sofa furniture, and plush toys.

Among them, the PLA Three-dimensional Crimped Staple can be pure PLA or mixed with other fibers, replacing existing polyester-related fillings.

Related product specifications:

PLA Three-dimensional Crimped Staple: 1.5Denier-5Denier, Length 38/51/64mm

Regular Fiber: 2 Denier , Length 38/51mm

Image | eSUNFiber PLA Three-dimensional Crimped Staple

Image | eSUNFiber Corn Fiber Health Quilt

Company Profile of eSUNFiber

EsunFiber (Suzhou) Co., Ltd. is a subsidiary of Shenzhen Esun Industrial Co., Ltd., mainly engaged in the PLA fiber&non-woven fabric business, striving to become a leading company in differentiated and functional PLA fibers. eSUNFiber’s PLA materials, PLA fibers, and non-woven fabrics are industry-leading. Among them, the PLA Bi-component Staple is a leading and distinctive product, with large-scale production and sales achieved in the development of PLA staples and bicomponent staples and differentiated products. The company’s PLA fiber and non-woven fabric products can be widely used in industries such as sanitary materials, clothing fabrics, home textiles and toy fillings, and medical supplies.