Combating Sand with Sand, Green Desertification Control—PLA Sand Barriers

From December 2 to 13, the 16th Conference of the Parties (COP16) to the United Nations Convention to Combat Desertification (UNCCD) was held in Riyadh, the capital of Saudi Arabia.

According to Guan Zhi'ou, head of the Chinese delegation to COP16 and Director of the National Forestry and Grassland Administration, China has achieved remarkable success in combating desertification. The country has continuously reduced the areas of desertified and sandy land, becoming the first globally to achieve zero net land degradation. Key treatment areas have witnessed a historic shift from “advancing deserts, retreating humans” to “advancing greenery, retreating deserts.” The economic, social, and ecological transformations in desertified regions have been profound. Particularly since June last year, China has launched an intensive campaign under the "Three-North Shelterbelt Program," treating 3.8 million hectares of desertified land. As of the end of 2023, China’s forest coverage rate has surpassed 25%, making it the global leader in greening efforts.

Technology has played a critical role in these achievements. This article focuses on the application of polylactic acid (PLA) sand barriers in desertification control projects.

Currently, PLA sand barriers are being used in desertified land management across Inner Mongolia, Shaanxi, Gansu, Ningxia, and other regions in China. But what are the specific advantages of this green technology based on PLA sand barriers?

1. Harnessing sand to combat sand, improving deployment efficiency

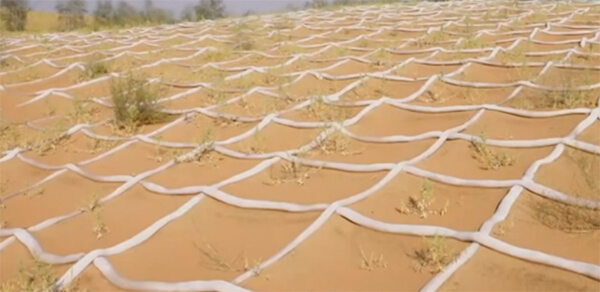

Sand barriers are typically made from locally sourced materials such as clay, wheat straw, reeds, straw, gravel, bricks, and branches. PLA fiber sandbag barriers use polylactic acid fiber fabric as the base material for sandbags. By filling them with sand on-site in desert regions, they become barrier structures, making transportation easier and installation more efficient.

2. Biodegradable, low-carbon, and eco-friendly

In the past, materials like nylon mesh, PE sand barriers, and PVC sandbags were effective for protection. However, these non-degradable materials gradually break down into fragments under environmental factors, infiltrating the soil and creating recovery challenges. This introduces new ecological pressures, undermining the overall sustainability of desertification control efforts.

PLA sand barriers, made from polylactic acid fibers, offer a renewable and biodegradable alternative. These fibers completely decompose into carbon dioxide and water in natural environments, leaving no secondary pollution or chemical residues.Additionally, due to the arid conditions in desert and semi-desert areas, where moisture is scarce, the hydrolysis process slows the biodegradation of PLA. This ensures a longer service life as the molecular weight decreases at a slower rate, making PLA fiber materials more durable.

eSUNFiber PLA fibers have been certified as biodegradable by Germany’s DIN.

3. Stable structure, long-term durability

Plant-based materials like wheat straw, reeds, and straw also offer effective windbreak and sand fixation. However, these materials decompose and decay easily, leading to shorter functional lifespans and requiring regular maintenance and replacement. This increases demands on human, material, and financial resources.

PLA sand barriers, on the other hand, possess excellent elasticity, ground adhesion, and anti-scouring properties. They are highly effective at windbreak and sand fixation. The knitted structure of PLA barriers offers superior stability, quickly forming stable wind-eroded concave surfaces and maintaining their integrity over time. With a long service life, they minimize the need for repeated installations, facilitating vegetation recovery and reducing maintenance costs.