Degradable PLA Fiber Promotes the Iterative Upgrade of Disposable Medical Products

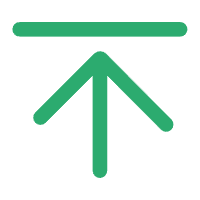

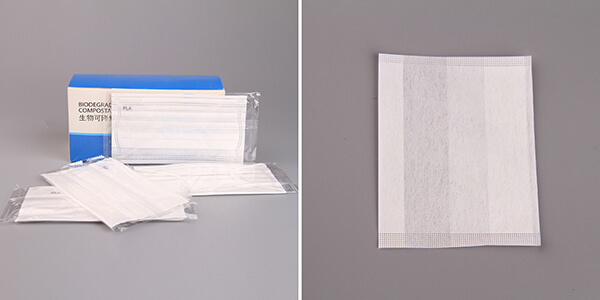

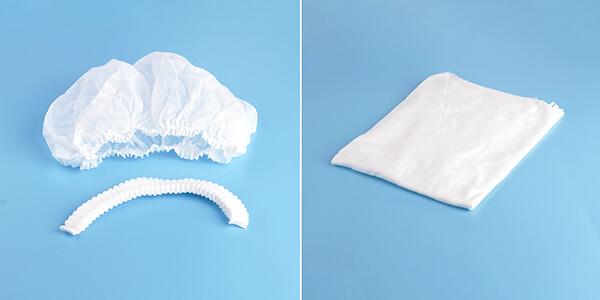

Against"low carbon and sustainable development," biobased degradable polylactic acid (PLA) fiber and nonwoven fabric have vast application prospects. In the medical field, PLA fibers can be used as medical consumables, such as medical dressings and bandages.The can alsoproduce disposable medical products, including masks, caps, shoe covers, protective clothing, pillowcases, bed sheets, bed covers, and more.

So, what are the advantages of PLA fibers in medical and healthcare materials in terms of product performance?

1. Biodegradability

PLA product waste can completely decompose into carbon dioxide and water within 3 to 6 months under industrial composting conditions (temperature of 58°C, humidity of 98%, and microbial conditions). In regular landfill conditions, PLA can degrade in 3 to 5 years. The use of PLA fibers and nonwoven fabrics in medical applications can significantly reduce the ecological pollution and harm caused by the large amounts of disposable medical waste generated daily.

*eSUNFiber’s PLA fibers and nonwoven fabrics have received the German DIN composting degradation certification.

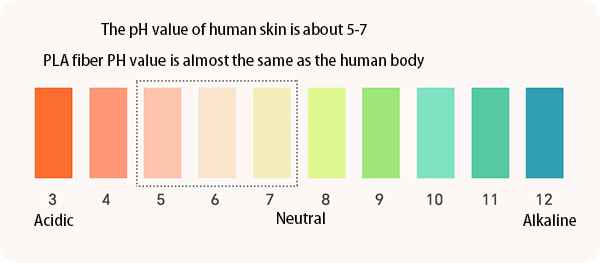

2. Natural Material, Skin-Friendly and Soft

PLA is a biobased material extracted from renewable plant resources, making it naturally safe and reducing skin irritation from chemicals.

Since PLA is derived from lactic acid, which is an endogenous substance in the human body, it has high biocompatibility and is non-allergenic. This means that disposable medical products made from PLA fibers are less likely to cause allergic reactions when in contact with the skin, making them suitable for sensitive skin.

In addition, PLA fiber nonwoven fabric products are soft to the touch, providing a comfortable user experience in practical applications.

3. Can Be Mixed with Wood Pulp or Other Natural Fibers

PLA fibers can be used alone, taking advantage of their unique sustainability, eco-friendliness, and functionality. Alternatively, they can be mixed with natural fibers or cellulose fibers (such as bamboo fibers or wood pulp fibers), forming a complementary combination that maintains biodegradability while enhancing strength and durability, lowering costs, and balancing performance and economy.

4. Breathable and Dry

PLA fibers are lightweight and have good hydrophobic properties, making products made from them relatively dry and breathable. They offer a comfortable user experience, especially suitable for medical and healthcare applications.

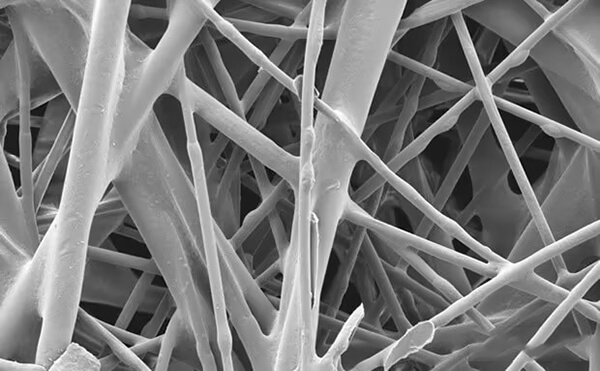

5. High Strength, No Shedding

PLA nonwoven fabric possesses excellent physical properties, such as high strength, and good resistance to friction and abrasion. When used in medical and healthcare materials, it is durable and not prone to wear, providing effective protective functions.

6. Supports Customization Needs

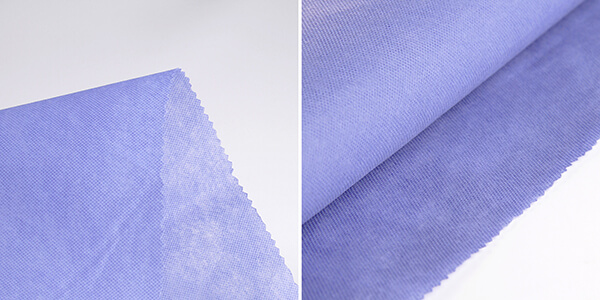

PLA nonwoven fabric can be customized with different colors (such as blue, green, etc.) through spinning processes or post-processing dyeing treatments to meet the needs of various medical consumables.

eSUNFiber focuses on the development and strategic growth of PLA fibers and nonwoven fabrics as its primary products. The company offers a wide range of PLA products, including various specifications of short fibers, yarns, and nonwoven fabrics, particularly differentiated PLA fibers such as bicomponent fibers and three-dimensional crimped fibers. Custom fiber and nonwoven fabric products can be tailored according to customer application needs.

Currently, eSUNFiber's production capacity includes a 10,000-ton/year melt-spun PLA fiber production line, three differentiated PLA fiber production lines with a capacity of 5,000 tons/year, capable of producing PLA three-dimensional crimped fibers, bicomponent composite fibers, specialty cross-section fibers, PLA yarns, and solution-dyed PLA fibers, as well as a 1,000-ton/year PLA Thermal Bonded/ Air Throughnonwoven fabric production line.