Reducing Impact for the Earth!Under the dual carbon goals, the hotel industry is actively pursuing energy-saving and low-carbon transformations in various ways. Polylactic acid (PLA) fiber, as a bio-based, biodegradable, and recyclable eco-friendly material, can provide significant environmental benefits to the hotel industry.

First, PLA fibers can be used to produce a wide range of disposable products.eSUNFiber’s PLA fibers and non-woven fabrics can be used to customize and produce biodegradable disposable slippers, towels, bath towels, shower caps, antibacterial toilet seat covers, disposable pajamas and sleeping bags, bedding sets, and more. They can also be applied in packaging scenarios, such as for disposable combs, toothbrushes, and cotton swab packaging.

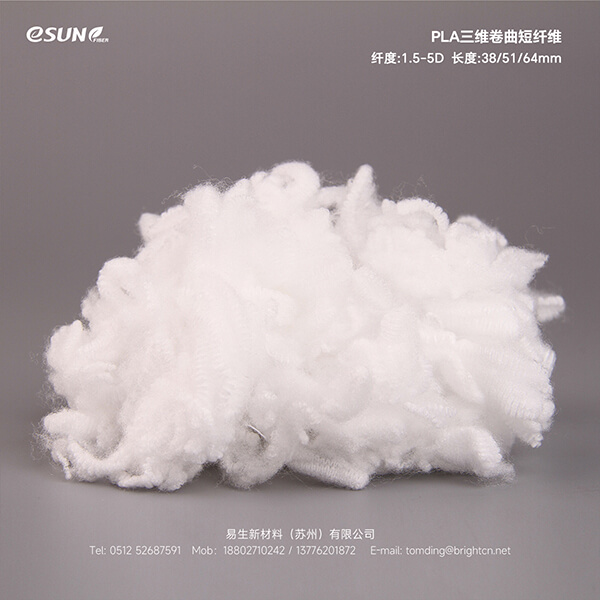

In addition,eSUNFiber’s PLA three-dimensional crimped staples can also be used as filling materials for home textiles and insulation materials for clothing. In the hotel industry, they can be applied to bedding, sofa furniture, cushions, and other fillings.

In the above specific applications, what are the characteristics and advantages of PLA fiber?

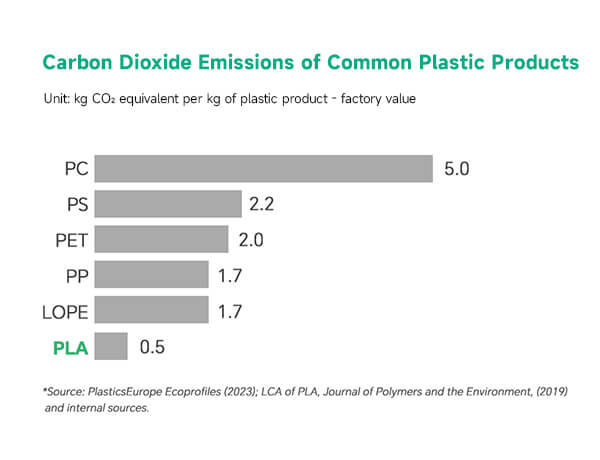

1.Low Carbon and Environmentally Friendly

Compared to traditional petroleum-based plastics, PLA has a significantly reduced carbon footprint. According to Plastics EUROPE, PLA’s global warming potential (GWP) is approximately 0.5 kg CO₂equivalent per kg, reducing the carbon footprint by about 75% compared to typical fossil-based polymers like PS, PET, PP, and PE.

2.Biodegradability

Derived from natural raw materials, PLA products decompose entirely into carbon dioxide and water within 3-6 months under industrial composting conditions (58°C, 98% humidity, and microbial presence). Even in landfill environments, PLA can degrade within 3-5 years.

It is worth noting that industrial composting of PLA requires specific conditions. PLA non-woven products exhibit good performance and a defined lifecycle in conventional environments.

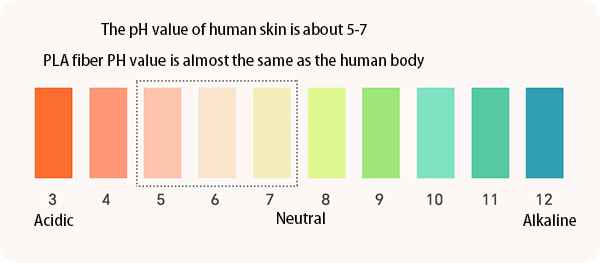

3.Skin-Friendly and Soft, Safe for Close Contact

As a bio-based material derived from renewable plant resources, PLA is naturally safe and reduces chemical irritation to the skin. Derived from lactic acid, a substance naturally present in the human body, PLA has high biocompatibility and is hypoallergenic. Whether used for disposable slippers, bedding sets, sleeping bags, towels, pajamas, or toilet seat covers, PLA is unlikely to cause allergic reactions. It is particularly suitable for sensitive skin.

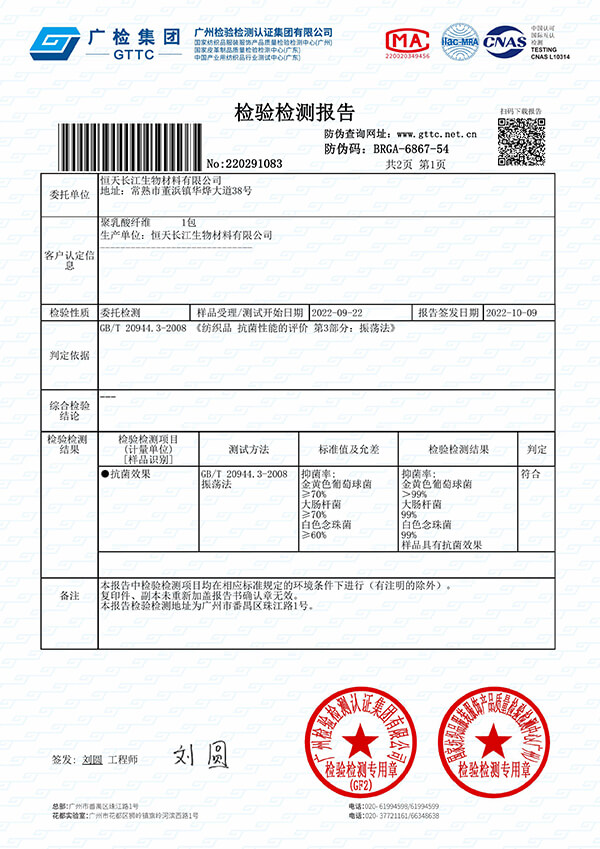

Additionally, the lactic acid-based weak acidity of PLA fiber surfaces provides natural antibacterial properties, effectively inhibiting mite growth while also offering anti-mold and odor-resistant benefits.

4.Strong and Durable, Resistant to Deformation and Shedding

PLA non-woven fabrics exhibit excellent physical properties, including high strength and resistance to shedding or linting after friction. This ensures a superior user experience when applied to disposable hotel products.

5.Blendable with Wood Pulp or Other Natural Fibers

PLA fibers can be used alone to maximize their sustainability, eco-friendliness, and functionality. They can also be blended with natural fibers or cellulose fibers (e.g., bamboo fiber, wood pulp fiber) to create complementary advantages. This approach retains biodegradability while enhancing strength and durability, lowering costs, and balancing performance with economic viability.

6.Excellent Elasticity

The molecular structure of PLA fibers provides excellent elasticity. eSUN’s PLA three-dimensional crimped staples, developed for home textile filling, offer outstanding resilience and fluffiness.

7.Flame Resistance, Low Smoke, and Non-Toxic

PLA fibers are not easy to burn, will go out immediately when away from fire, does not emit any black smoke or toxic gas, and is very safe to use.