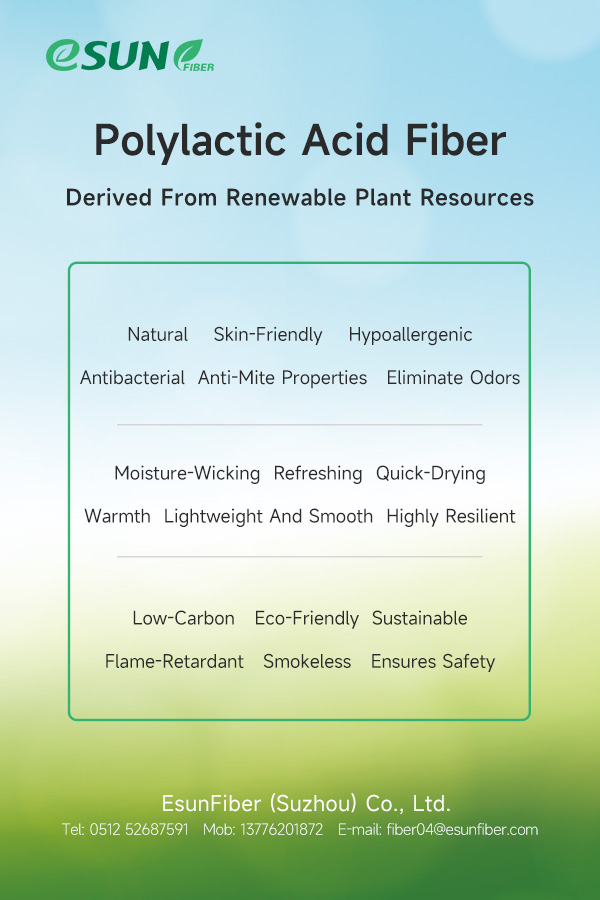

PLA fiber Filament and staple fibers both belong to textile fibers. Polylactic acid filament is a collection of fibers formed by stretching, twisting, or deforming multiple long monofilaments. Among them, polylactic acid multifilament includes dozens of monofilaments in one yarn, which can be used directly or spun into differentiated polylactic acid yarns. Polylactic acid monofilament, due to its unique properties, is widely used in fields such as medical suturing, fishing, tea bags, etc.

This article will mainly introduce the performance and application of EsunFiber PLA Monofilament, FDY Fully Drawn Yarn, DTY Draw-Textured Yarn.

Image | EsunFiber DTY Draw-Textured Yarn Product Example

1. PLA Monofilament

The raw material for polylactic acid monofilament is extracted from renewable plant resources, with an abundant and fully degradable source. PLA monofilament is mainly used for making disposable food packaging such as tea bag-related packaging. Additionally, due to its compatibility and biodegradable characteristics, PLA monofilament is also widely used in the medical field, such as self-dissolving surgical sutures, disposable surgical gowns, absorbent sanitary products, etc.

2.FDY Fully Drawn Yarn

FDY fully drawn yarn refers to the yarn that is made from polylactic acid and is stretched during the spinning process, resulting in a yarn with high orientation and medium crystallinity. Because it has been fully stretched, it can be directly used in textile processing to produce various types of wearable fabrics. FDY fabric feels smooth and soft, with a wide range of applications, often used to weave imitation silk and other wearable fabrics, or used in the home textile field.

Characteristics of FDY Fully Drawn Yarn:

①PLA filament yarn is more skin-friendly than polyester filament, with slightly lower tensile strength. However, the initial modulus and elongation at break of PLA filament yarn are higher than silk, with little difference in tensile strength. Overall, the mechanical properties of PLA filament yarn fully meet the needs of civilian textiles, especially in close-fitting wear, where its functionality is outstanding.

②The elastic recovery of PLA Filament yarn is good, better than silk, and close to viscose, but lower than polyester and nylon.

③PLA filament yarn has good chemical resistance and can withstand bleaching agents, oxidants, hydrocarbons, ketones, petroleum products, and inorganic acids. It is resistant to dilute alkali and not prone to mold, but hot alkali can cause it to decompose. It also strongly resists acids and alkalis and can withstand ultraviolet rays.

④ Easy to wash and quick to dry. Garments made of polyester fiber material can be washed and dried quickly and are widely used in outdoor products.

⑤ The material is environmentally friendly and 100% biodegradable after composting, causing no environmental pollution.

EsunFiber's PLA FDY filament product specifications mainly include 30D/36F, 75D/36F, 100D/36F, etc., which can be widely used in spinning, weaving, and then applied to clothing, home textiles, tea bag threads, and surgical sutures, among others.

3.DTY Draw-Textured Yarn

DTY draw-textured yarn is made by using POY as the original yarn, which is processed by stretching and false-twist texturing, giving it a certain degree of elasticity and shrinkage. Specifically, it utilizes the thermoplasticity of synthetic fibers to first add twists and then untwist, resulting in a bent shape similar to a spring. It appears twisted but is false-twisted, also commonly known as elastic yarn, available in high-elasticity and low-elasticity types.

The application fields of DTY Draw-Textured Yarn are broad and suitable for knitting, weaving, and tube yarn dyeing, among others. It has a fluffy hand feel and holds broad prospects, especially in underwear, bedding, sports, and casual wear.

EsunFiber product application show:

EsunFiber focuses on developing and strategically expanding polylactic acid fiber and non-woven fabrics as main products. EsunFiber has one 10,000 tons/year melt-spun polylactic acid fiber production line, one 1,000 tons/year polylactic acid hot air non-woven fabric production line, and three functional polylactic acid fiber production lines. Among them, the three functional polylactic acid fiber production lines have an annual capacity of 5,000 tons and can produce various differentiated products such as three-dimensional curled fibers, dual-component PLA fibers, profiled fiber, polylactic acid yarn, and solution-dyed polylactic acid fibers.

Welcome interested customers to consult and discuss cooperation!