Application of Polylactic Acid Non-woven Fabric in Air Filtration Materials

Polylactic acid (PLA) non-woven fabric materials combine the inherent advantages of PLA with the structural characteristics of non-woven fabrics, such as ultra-fine fibers, large specific surface area, and high porosity. These properties make PLA non-woven fabrics highly promising in the field of air filtration.

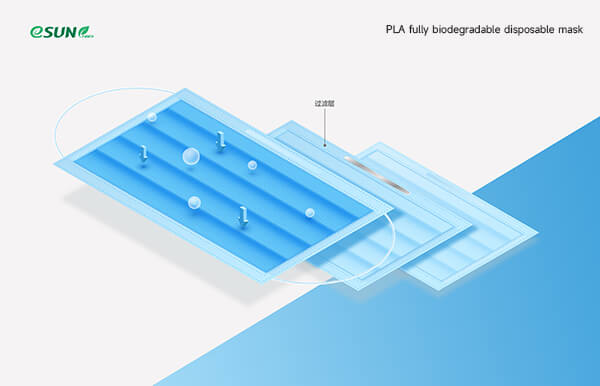

The application of PLA non-woven fabrics in the air filtration industry can mainly be categorized into mask filter materials and eco-friendly filtration materials (e.g., industrial dust filtration, air purification, personal protection, etc.).

So, what are the advantages of using PLA non-woven fabric as an air filtration material?

1.Biodegradability

For mask filter materials, biodegradability is a crucial feature.Traditional mask filter layers typically use double-layer melt-blown PP non-woven fabric, which is almost non-degradable. Discarded masks, whether they end up in rivers, oceans, or buried in soil, pose significant harm to the ecosystem.

Mask filter layers made from PLA not only effectively filter harmful substances like dust and bacteria from the air, but they also degrade after disposal, reducing the burden on ecosystems.

PLA fiber products can be completely decomposed by microorganisms into carbon dioxide and water when placed in a natural environment with certain temperature and humidity conditions (such as sandy soil, sludge, seawater). If PLA fibers are buried in soil, the natural degradation time is about 2 to 3 years; if mixed with organic waste and buried, it decomposes within a few months.

In industrial composting conditions (temperature of 58°C, humidity of 98%, and presence of microorganisms), PLA product waste can completely decompose into carbon dioxide and water within 3 to 6 months.

eSUNFiber's PLA fibers and non-woven fabrics have obtained German DIN compostability certification and US BPI degradability certification.

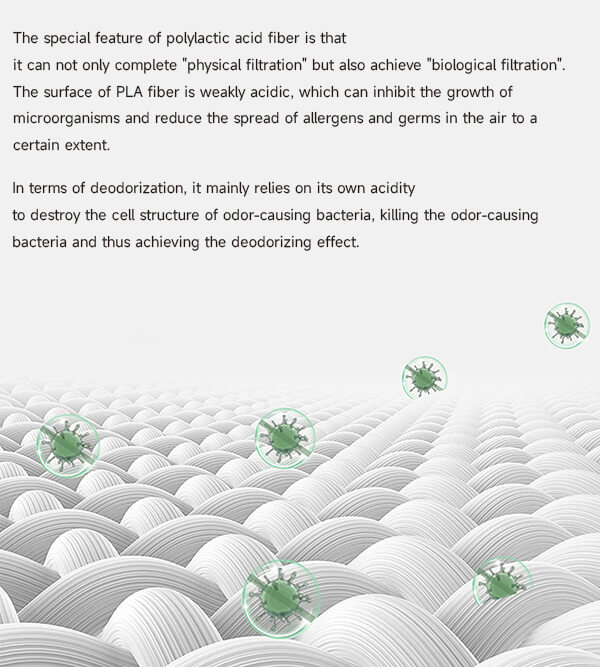

2.Antibacterial and Deodorizing

Due to this characteristic, disposable biodegradable masks made from PLA offer significant deodorizing effects, ensuring no bad breath even with long-term wear. When used in household air filtration devices, the filtered air remains fresh and odorless, while effectively preventing mold and adhesion on the filter material, thereby extending its lifespan.

3. Filtration Performance

4. High Breathability

5. Good Tensile Strength

6. Strength and Toughness

With societal progress and technological innovation in the textile field, PLA materials with richer functionalities will provide users with more options.

eSUNFiber is primarily dedicated to the research, production, and sales of PLA fibers and non-woven fabrics. Interested users are welcome to inquire and learn more, as we explore innovative applications of PLA fibers together!