New Force in Thermal Bonding Applications: Unique Advantages of PLA Bi-component Staple

Thermal bonding fibers are materials that achieve fiber-to-fiber bonding through a heat treatment process. This technology is commonly used in the production of non-woven fabrics, composites, and other products that require fiber bonding.

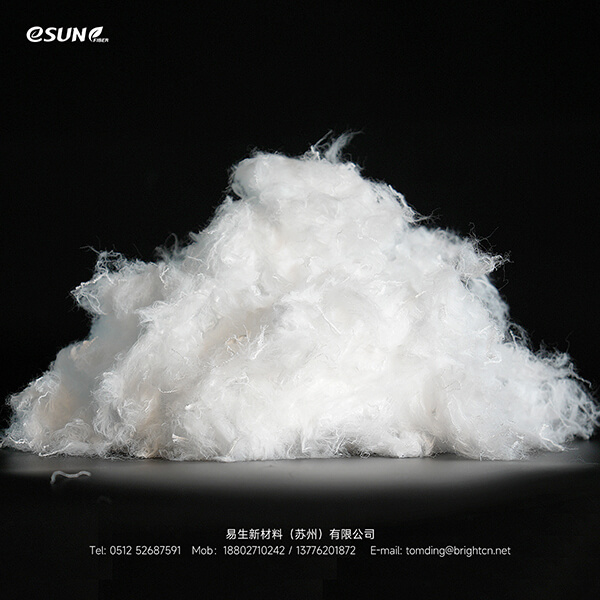

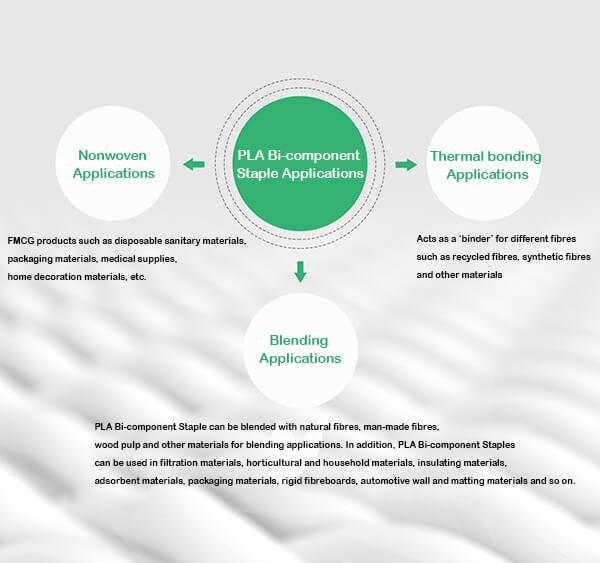

eSUNFiber PLA Bi-component Staple can be used as thermal bonding fibers. In practical applications, PLA thermal bonding fibers exhibit excellent thermal bonding performance, along with good biocompatibility and biodegradability, providing various enhanced properties to non-woven fabric products. This offers broad development prospects.

1.Excellent Thermal Bonding Performance

Good thermoplasticity: PLA fibers can melt and form an adhesive at the appropriate temperature, making them very suitable for thermal bonding processes.

Stable melting point: PLA fibers have a relatively low melting point (usually in the range of 150-180°C), allowing effective bonding between fibers during the thermal bonding process.

2.Wide Applicability

eSUNFiber PLA Bi-component Staple can be combined with natural fibers such as linen, cotton, wool, and silk, as well as with cellulose fibers like viscose, lyocell, modal, and bamboo fibers. In the non-woven fabric field, it can replace conventional low-melting-point polyester fibers and ES fibers, enabling the production of fully biodegradable materials.

3.Enhanced Performance

When mixed with natural fibers, man-made fibers, wood pulp, and more, PLA Bi-component Staple can significantly enhance the strength of non-woven fabrics through dry or wet non-woven fabric processing techniques. At the same time, it imparts moisture-wicking, breathability, antibacterial, and deodorizing properties to natural fiber-based products, comprehensively improving the performance of non-woven fabrics.

4.Easy to Process

Due to the thermal bonding characteristics of PLA fibers, they can form seamless connections through simple heat treatment during manufacturing, reducing complex processing steps.

5.Environmentally Friendly

The use of PLA Bi-component Staple for thermal bonding eliminates the need for adhesives, offering environmental benefits since no additional components require handling. Additionally, PLA fibers are biodegradable, providing a more sustainable and eco-friendly solution for product upgrades.

eSUNFiber PLA Bi-component Staple

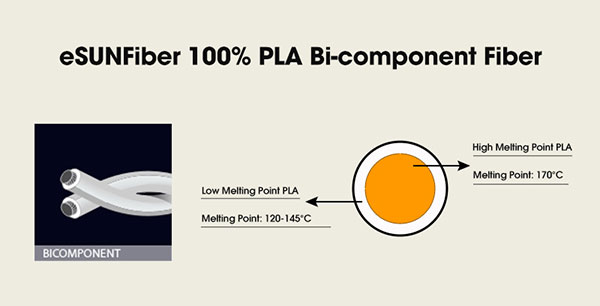

eSUNFiber PLA Bi-component Staple is a bi-component core-sheath composite fiber made of 100% PLA. The sheath layer is made of low-melting-point PLA with good softness, while the core layer is composed of high-melting-point PLA with high strength.

After heat treatment, the sheath partially melts to play a bonding role, while the remainder retains its fiber form. The fibers interconnect without the need for adhesives, forming a non-woven fabric structure with the additional feature of low thermal shrinkage.

PLA Bi-component Staple has broad processing adaptability, making it particularly suitable for producing sanitary materials, thermal insulation fillers, filtration materials, and more using hot air-through technology. It is also the best choice for all biodegradable non-woven fabrics, adhesive-free cotton, and natural composite board bonding materials.

PLA Bi-component Staple is a leading and featured product of eSUNFiber. With mature production technology and stable product quality, we welcome inquiries from all users. If you have any needs, feel free to contact us directly!