New Hotspot in Packaging Materials – Biodegradable Polylactic Acid (PLA) Non-woven Fabric

In the packaging industry, "low carbon" and "sustainability" have gradually become key focuses. Major brands are enhancing the eco-friendliness of their final products through design, production, and the selection of environmentally friendly materials.

Currently, polylactic acid (PLA) non-woven fabric, which has good biodegradability and practical functionality, is emerging as a new popular packaging material. Specifically, PLA non-woven fabric used as packaging material has the following characteristics:

1. Eco-friendliness

The eco-friendliness of PLA fibers and non-woven fabric can be summarized in three key points: “Bio-based, Biodegradable, Recyclable.”

PLA fiber non-woven products can be completely decomposed by microorganisms into carbon dioxide and water when in certain natural environments (such as sand, sludge, or seawater). PLA waste can fully decompose into carbon dioxide and water within 3-6 months under industrial composting conditions (temperature: 58°C, humidity: 98%, and microbial activity). Even in a regular landfill environment, it can degrade within 3-5 years.

It is worth noting that the industrial composting of PLA requires specific conditions. When used as packaging material, PLA non-woven fabric products have a certain life cycle and good performance in standard environments, providing stable protection for the packaged goods during various transportation scenarios, such as land, rail, sea, and air transport.

DIN Certified Compostable

eSUN's PLA fibers and non-woven fabrics have passed the German DIN certification for compostability.

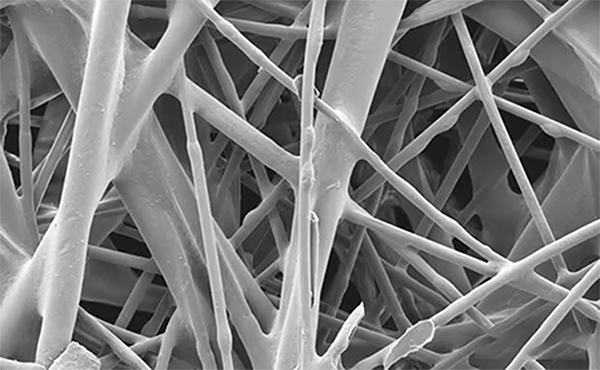

2. Good Mechanical Properties

PLA non-woven fabric has good mechanical properties, including a certain degree of strength and tear resistance, allowing it to withstand pressure and impact. In practical applications, it can serve as cushioning protection for packaged goods.

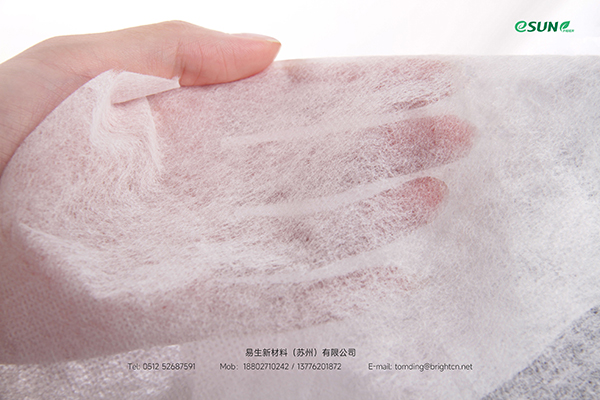

3. Soft and Scratch-resistant

PLA fibers and non-woven fabrics also possess good softness, making them suitable for packaging applications where they provide excellent protection for the packaged product. They do not damage the surface finish or appearance of the product, thus ensuring the quality of sales and user experience.

4.Good Texture and No Lint Shedding

PLA non-woven fabric has a high-quality texture and does not shed lint, maintaining the aesthetic appeal of the product and ensuring a good sales experience.

5. Cushioning and Shock Absorption

PLA fibers can not only be used in product packaging but can also be made into PLA padding, providing additional cushioning and shock absorption protection for the products.

6. Naturally Sourced and Suitable for Food Packaging

PLA fibers are derived from renewable plant resources such as corn, potatoes, and agricultural crop stalks. They possess excellent biocompatibility, biodegradability, antibacterial properties, and breathability, making them widely applicable in the packaging of food, pharmaceuticals, and fresh products, including fruit preservation, tea bags, coffee bags, and other bio-based packaging materials.

7. Low Flammability, Low Smoke, and Non-toxic

PLA fiber is self-extinguishes when removed from fire, with no black smoke or toxic gas

emissions, ensuring high safety in use.

8. Wide Applicability

PLA fibers can be blended with other cellulosic fibers (such as bamboo fibers, viscose fibers, etc.). This can lower costs while maintaining the full degradability of the packaging products. It also allows for more functional packaging products to meet different application needs.

Additionally, PLA fibers are highly adaptable and can be customized according to user requirements, making them suitable for various shapes and sizes of packaging.

Under the global trend of carbon reduction, PLA fibers and non-woven fabrics, as environmentally friendly materials, will inject green productivity into downstream industry applications.

eSUNFiber is primarily engaged in the research, development, production, and sales of PLA fibers and non-woven fabrics. We welcome interested users to inquire and explore innovative applications of PLA fibers together!