Biodegradable · Natural skin-friendly · Antibacterial · Anti-mite · Anti-allergy

More

PLA fiber, due to its excellent physical and mechanical properties, environmental friendliness, and biocompatibility, has a wide range of application prospects in the field of non-woven fabrics.

More

Polylactic acid fiber can be used for spinning, and it can be spun purely or blended with other fibers such as cotton, linen, silk, wool, viscose, and lyocell to produce fabrics of various styles.

More

The natural antibacterial, anti-mite, anti-mold, and flame-retardant properties of polylactic acid fiber make it suitable for the home textile field.

More

Polylactic acid fiber, due to its softness, durability, and ease of processing, is often used for toy filling and pet products.

More

PLA non-woven fabric, with its soft, lightweight, non-deformable, and moisture-proof characteristics, has a wide range of applications in packaging materials, including clothing packaging, footwear packaging, food packaging, and more.

More

The molecular structure of polylactic acid fiber has micropores and a rough texture, allowing the fiber surface to firmly retain the products of chemical reactions with tar components and low molecular substances, effectively adsorbing and removing harmful substances during the silk bundle filtration process, thus improving the filtration effect.

More

The biodegradability, durability, and UV resistance of polylactic acid fiber make it widely used in the agricultural field. It can be used to make agricultural ropes, nets, etc., which are durable and can resist the erosion of ultraviolet rays, extending their service life and reducing the generation of agricultural waste.

More

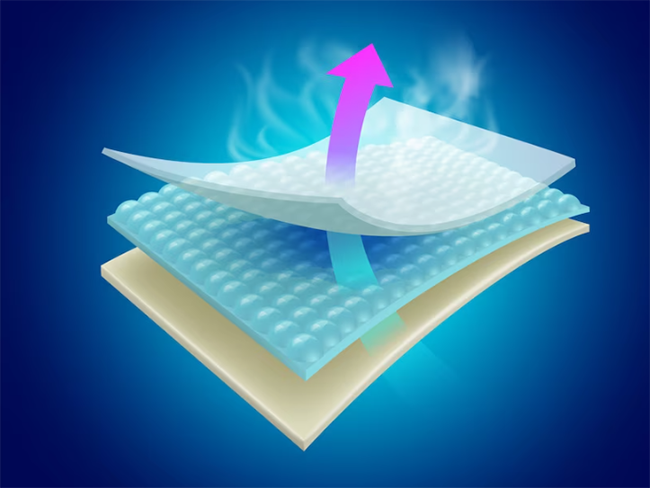

PLA fiber has a very wide range of applications in the medical and health product fields. Its unique biocompatibility, degradability, and safety make it an ideal material in these areas.

MoreEsunFiber (Suzhou) Co., Ltd. focuses on developing and strategically expanding polylactic acid fiber and non-woven fabrics as main products. eSUN Fiber has one 10,000 tons/year melt-spun polylactic acid fiber production line, one 1,000 tons/year polylactic acid hot air non-woven fabric production line, and three functional polylactic acid fiber production lines. Among them, the three functional polylactic acid fiber production lines have an annual capacity of 5,000 tons and can produce various differentiated products such as three-dimensional curled fibers, dual-component PLA fibers, profiled fiber, polylactic acid yarn, and solution-dyed polylactic acid fibers.